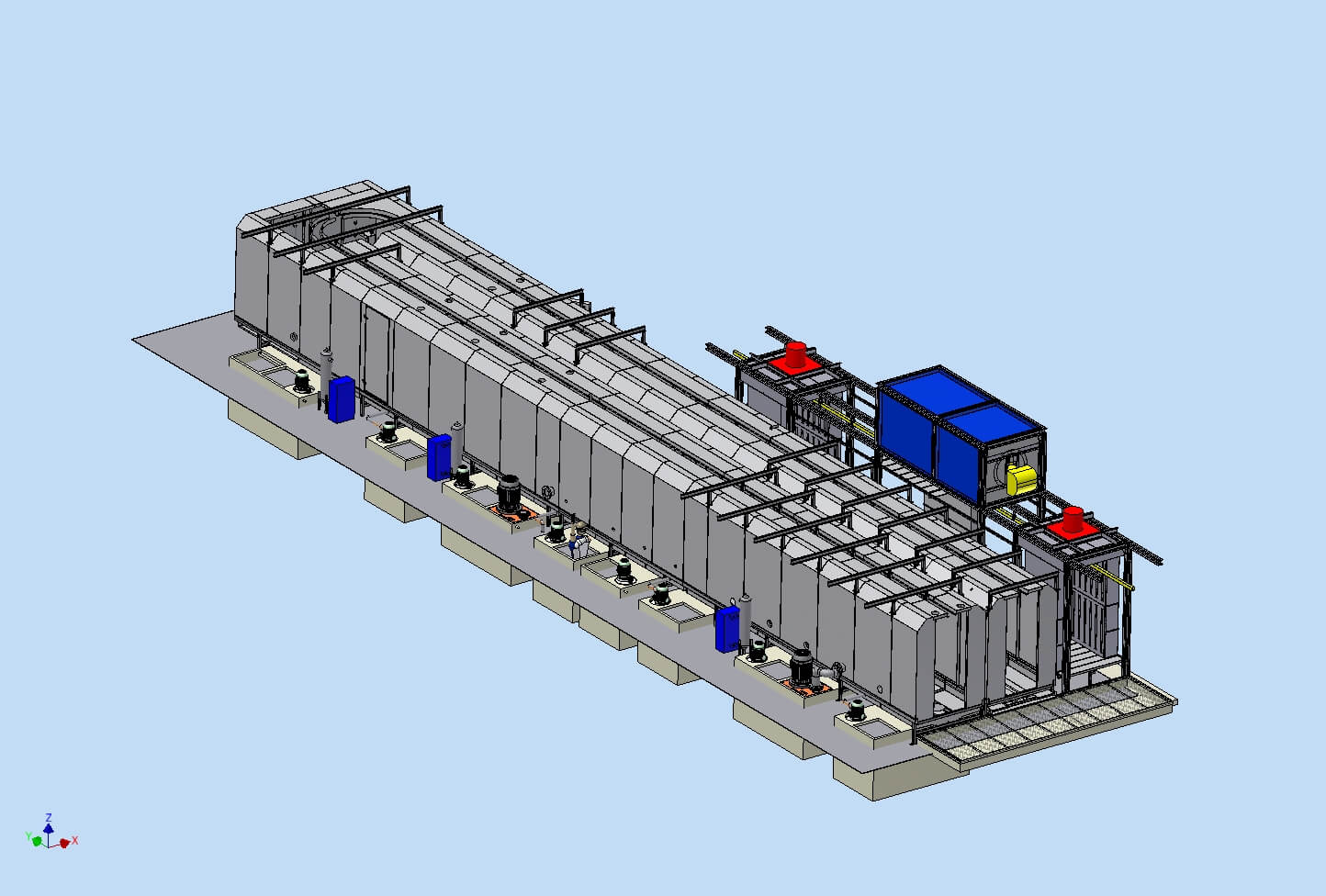

Industrial supply

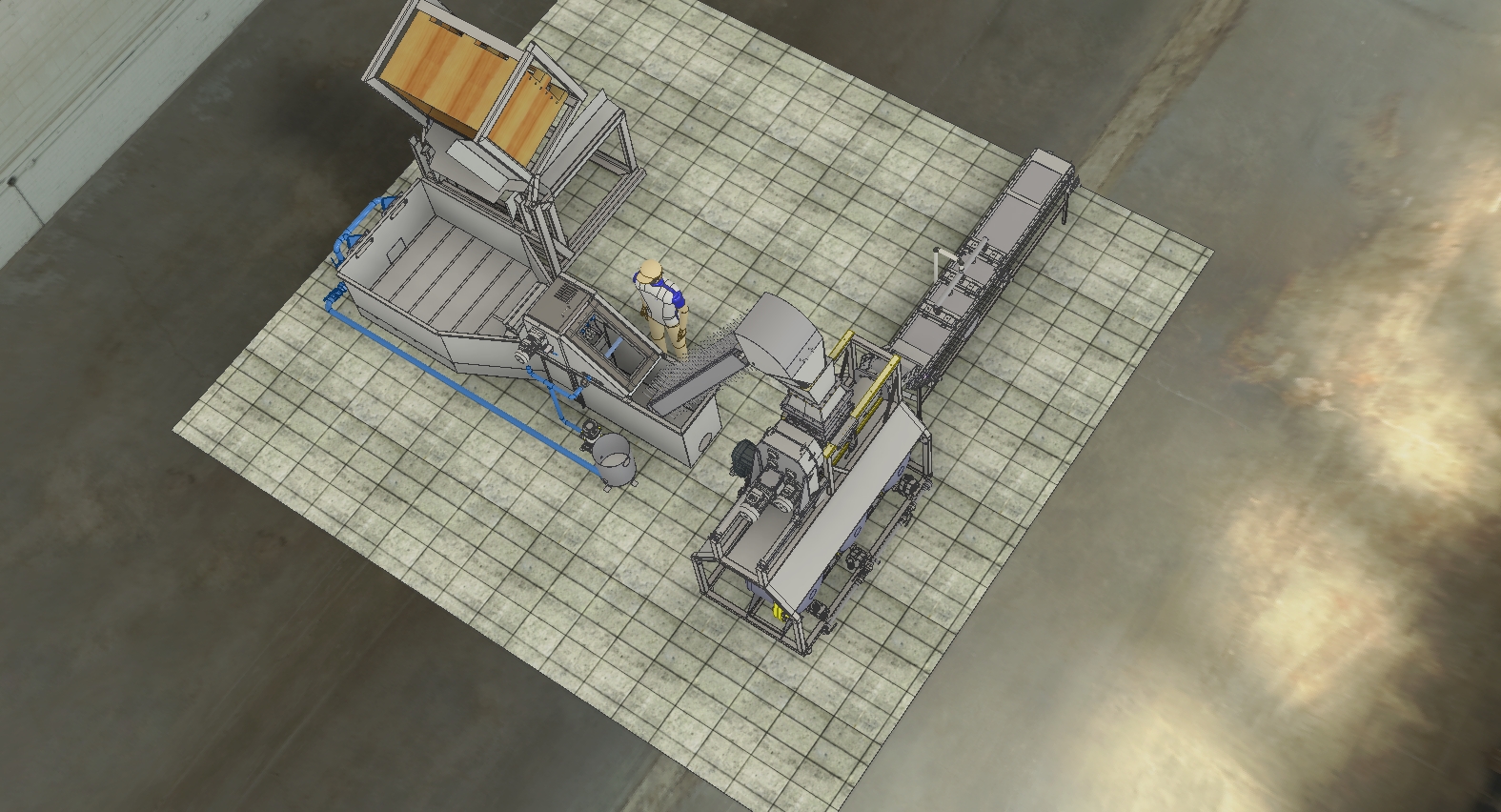

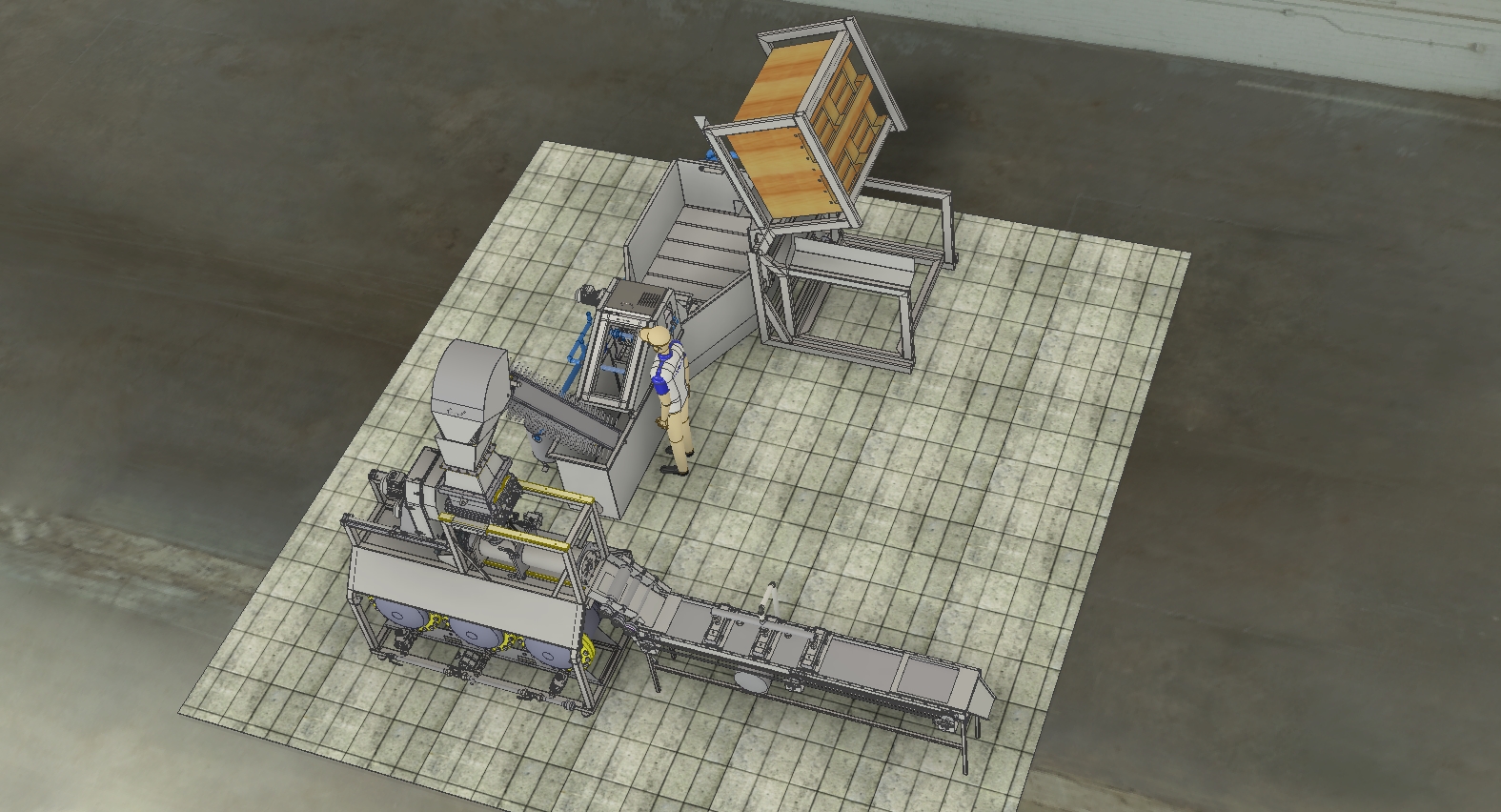

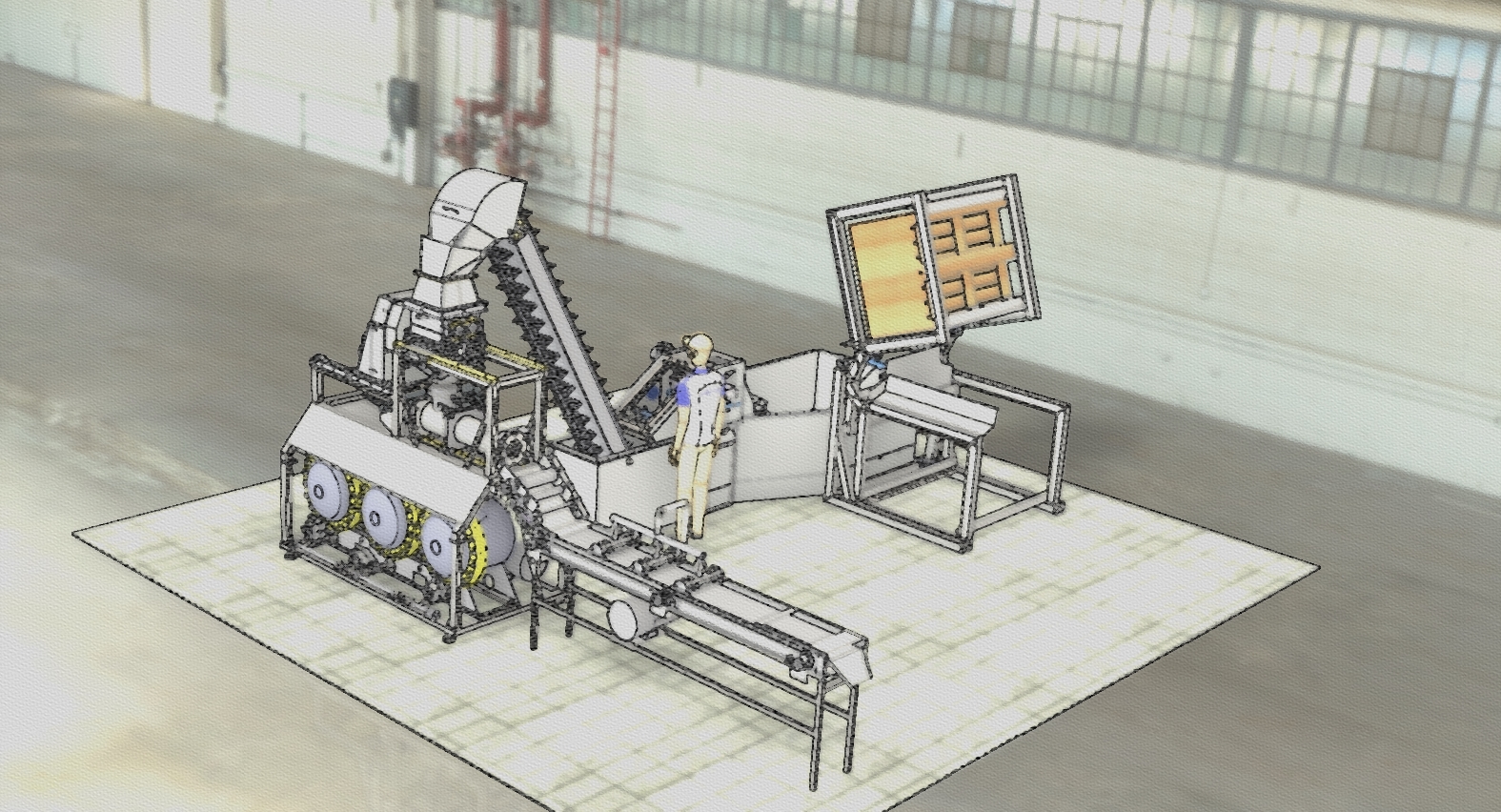

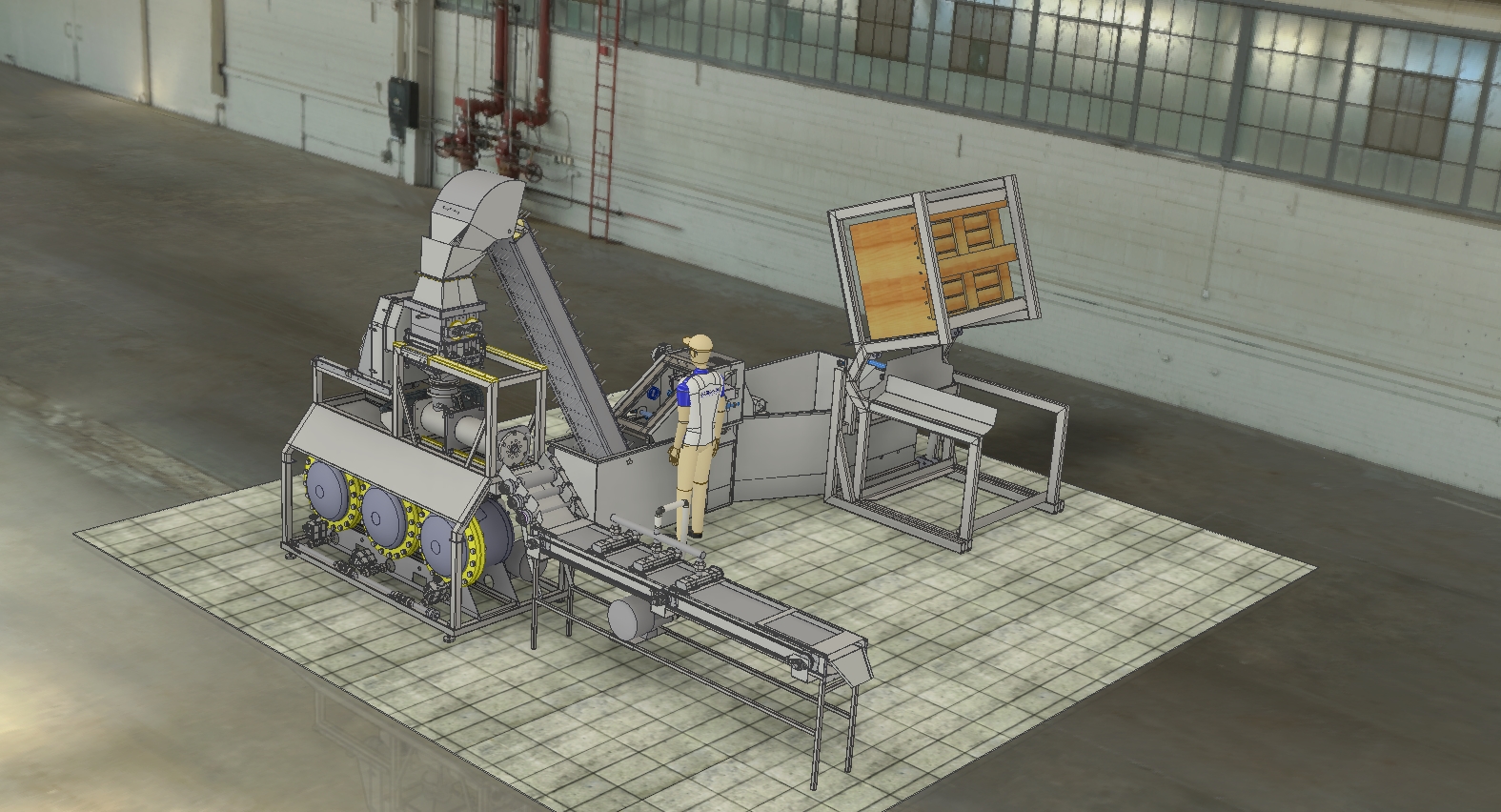

Our workflow

Single pieces, or smaller series…

Whether it’s a simple lasered image, or a more complicated composition, …

we can handle anything.

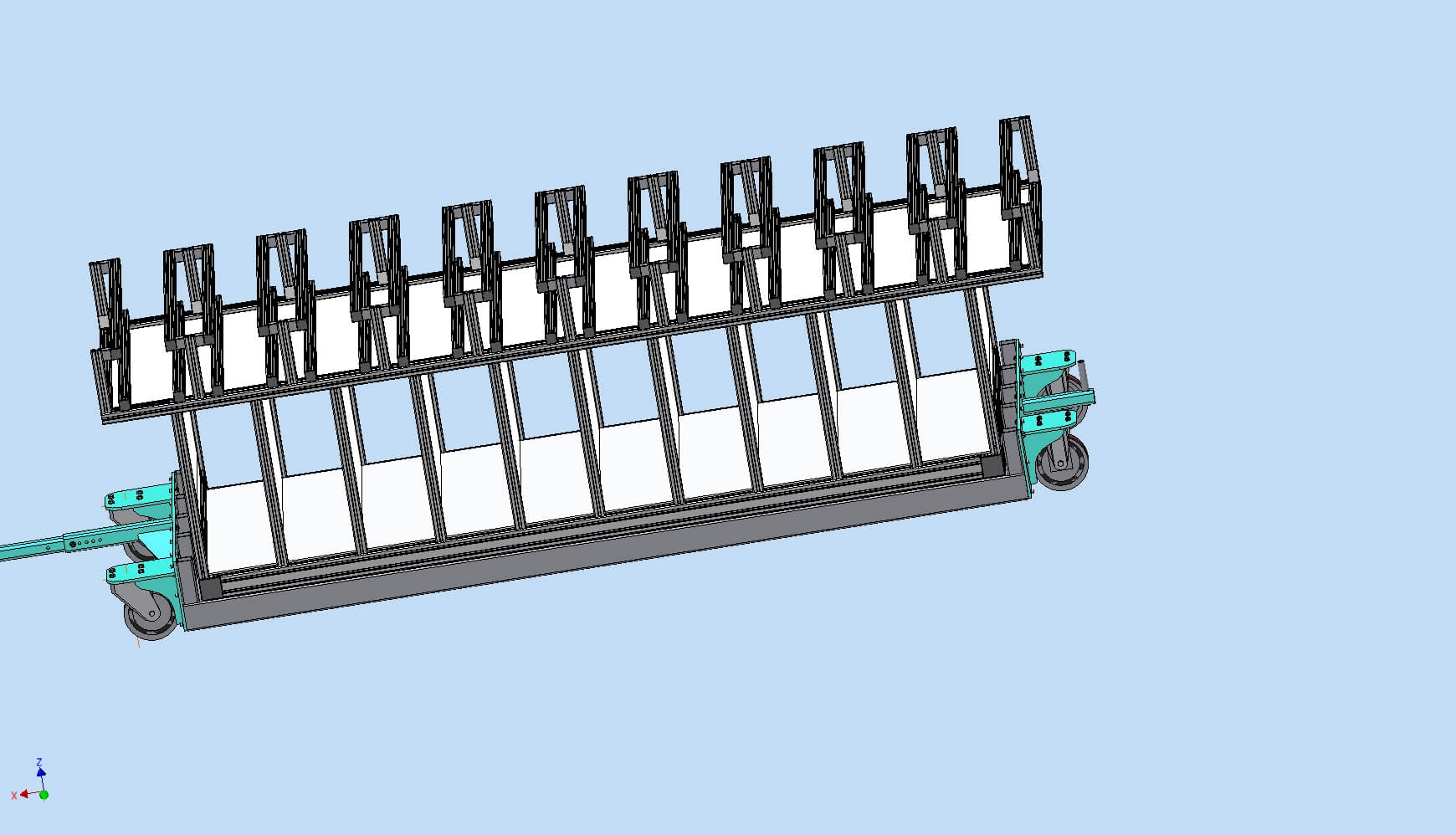

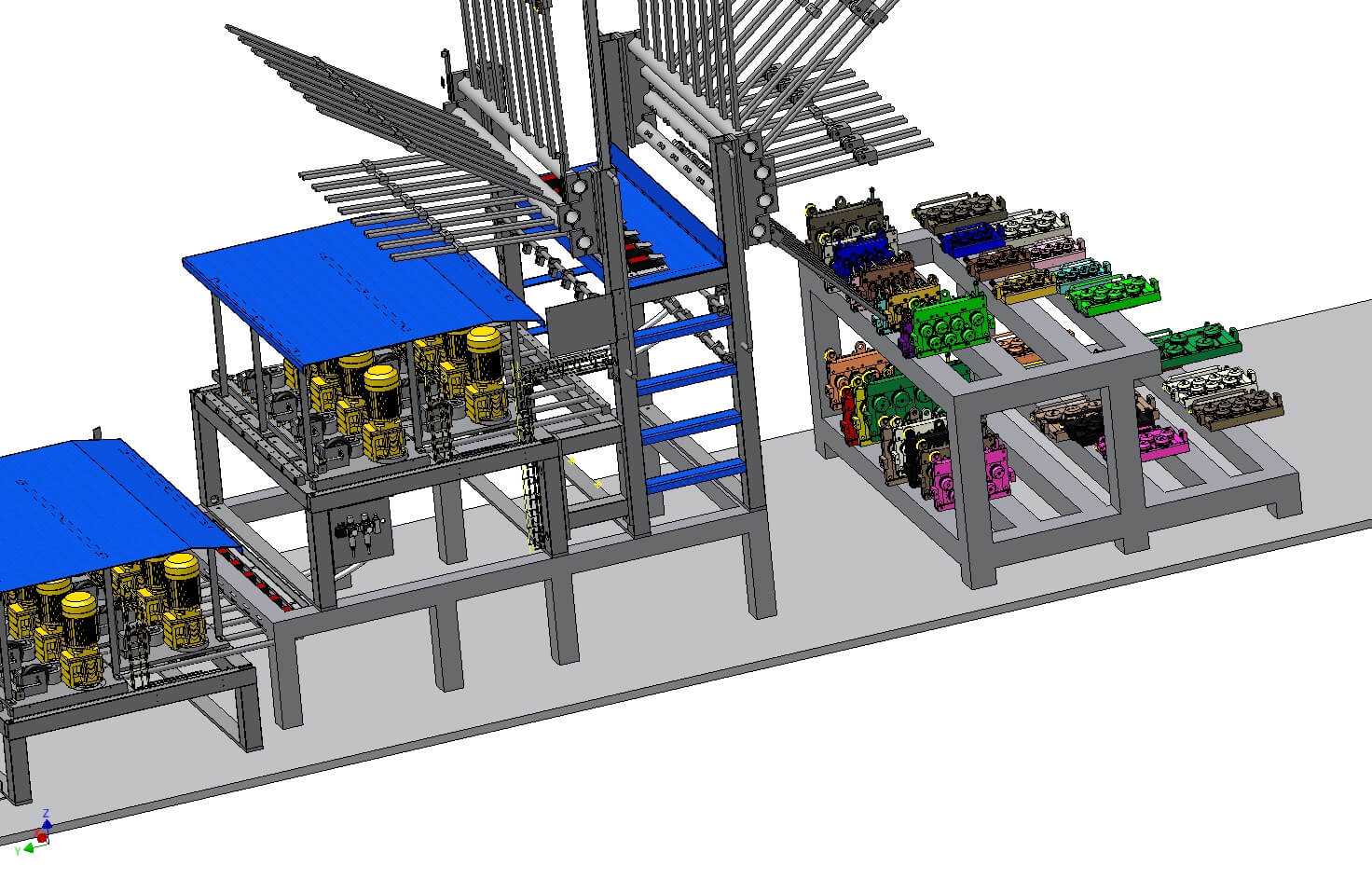

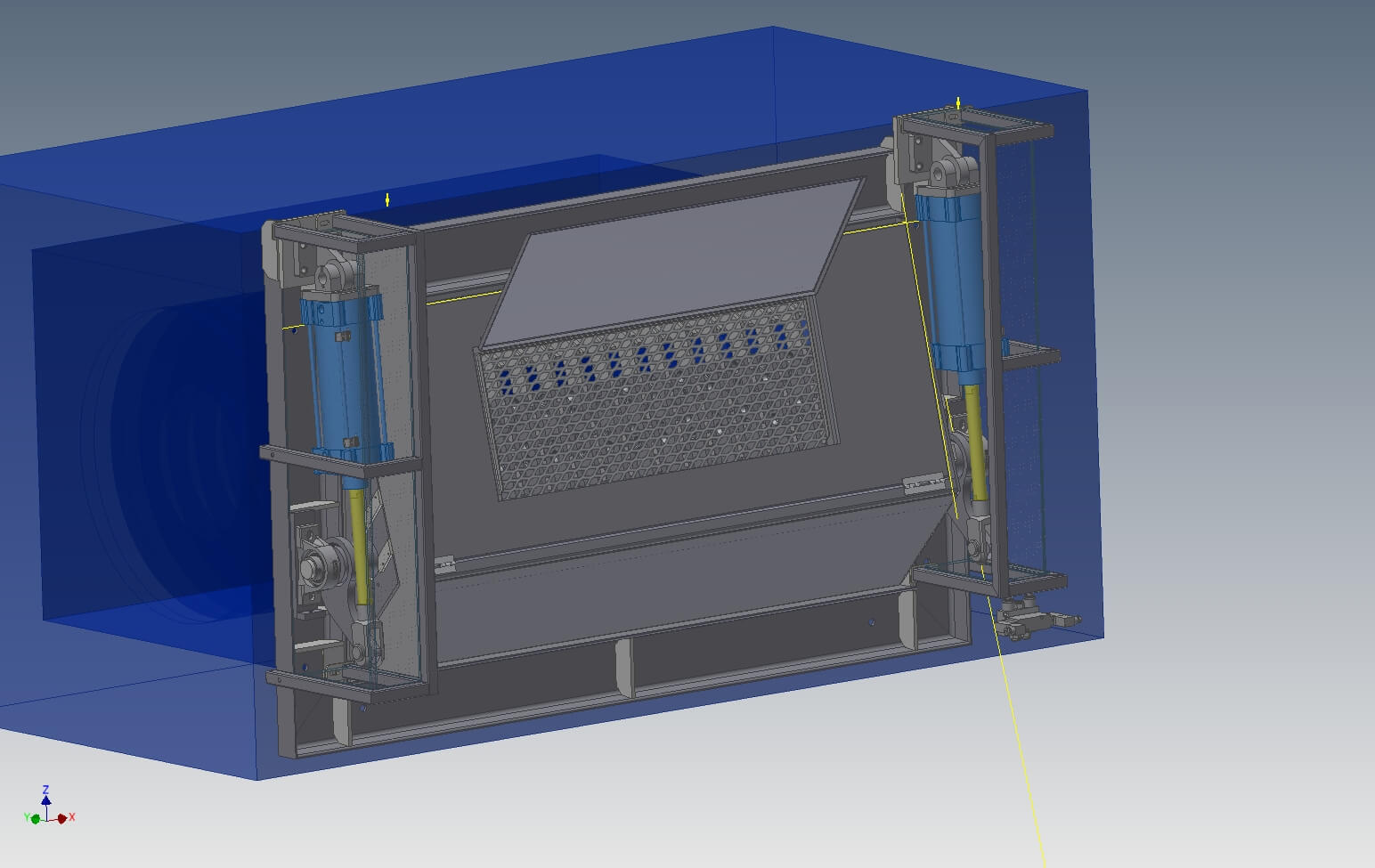

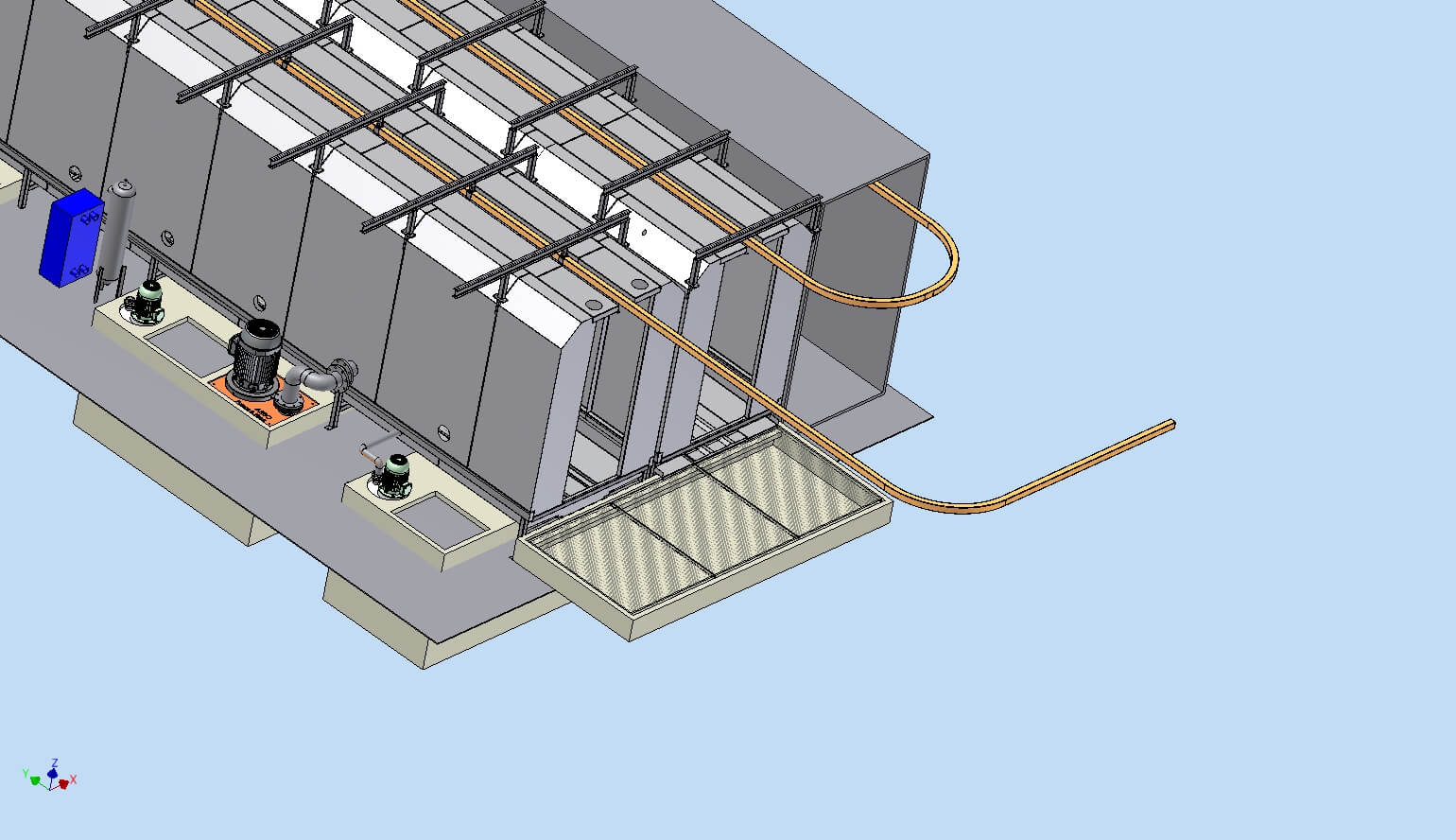

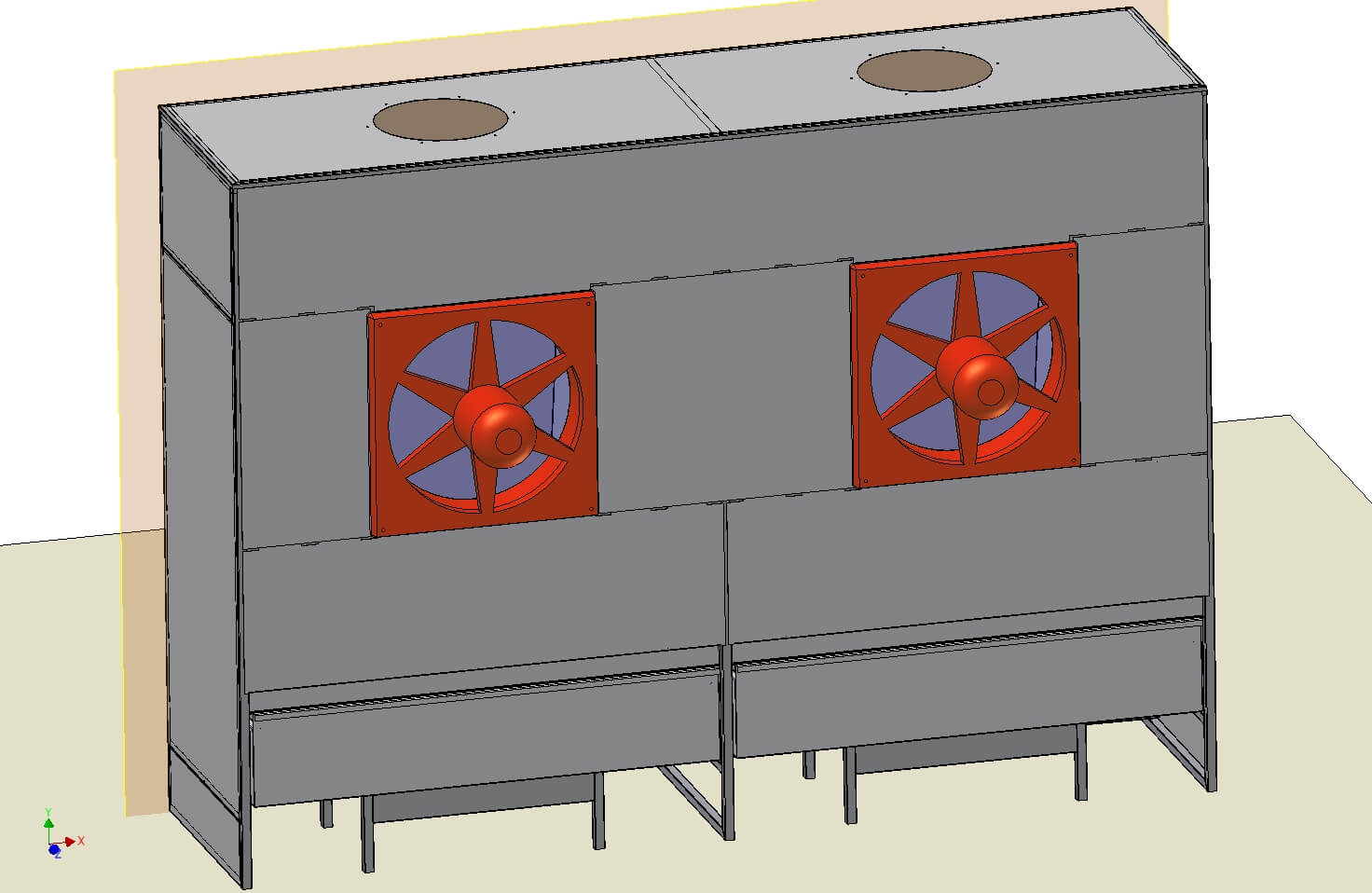

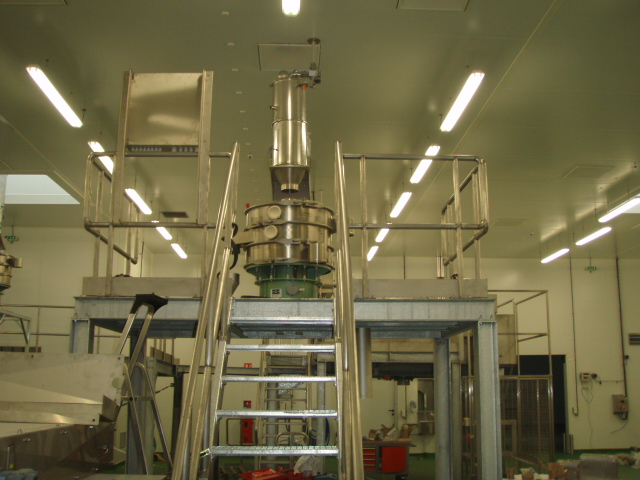

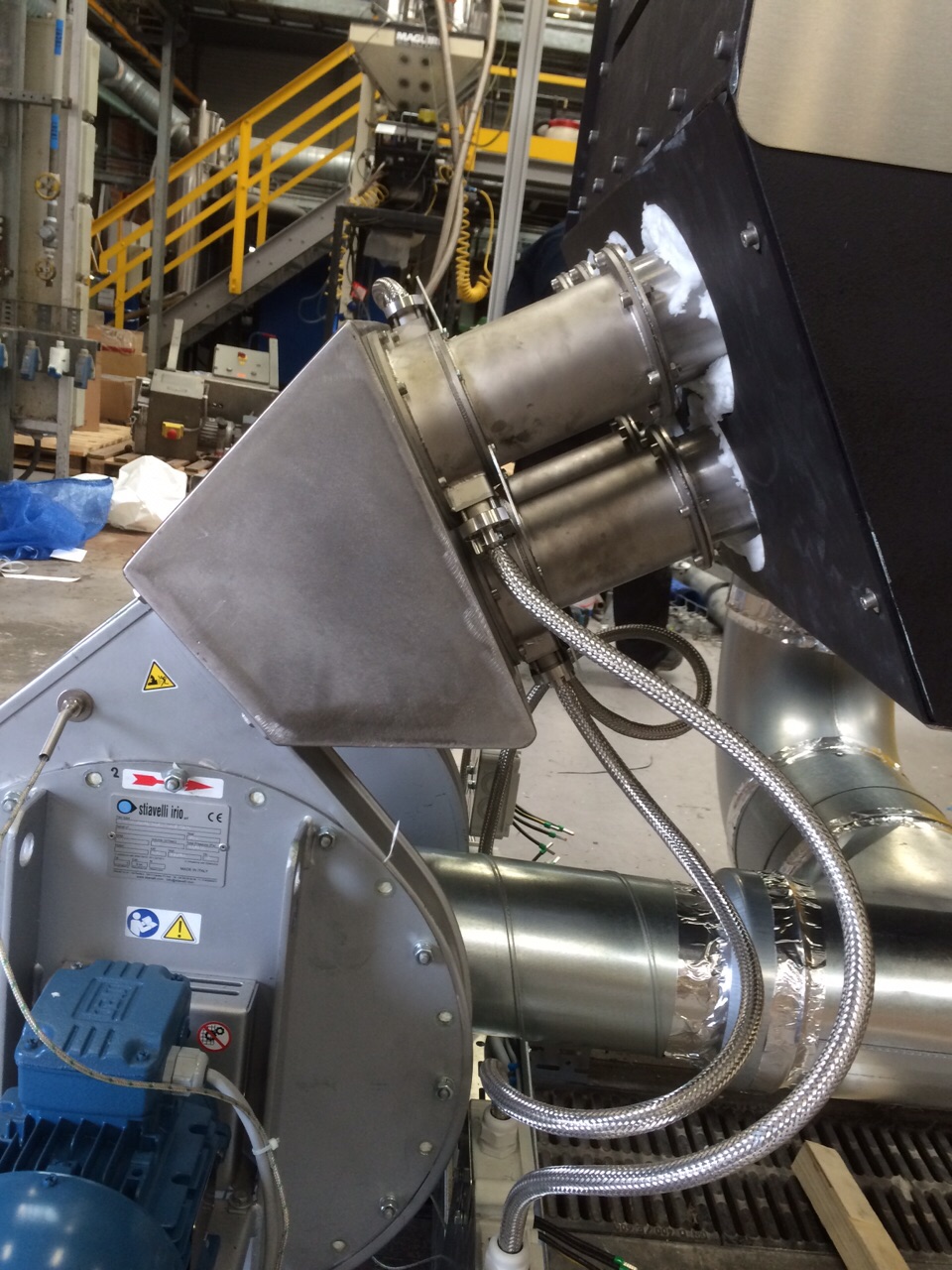

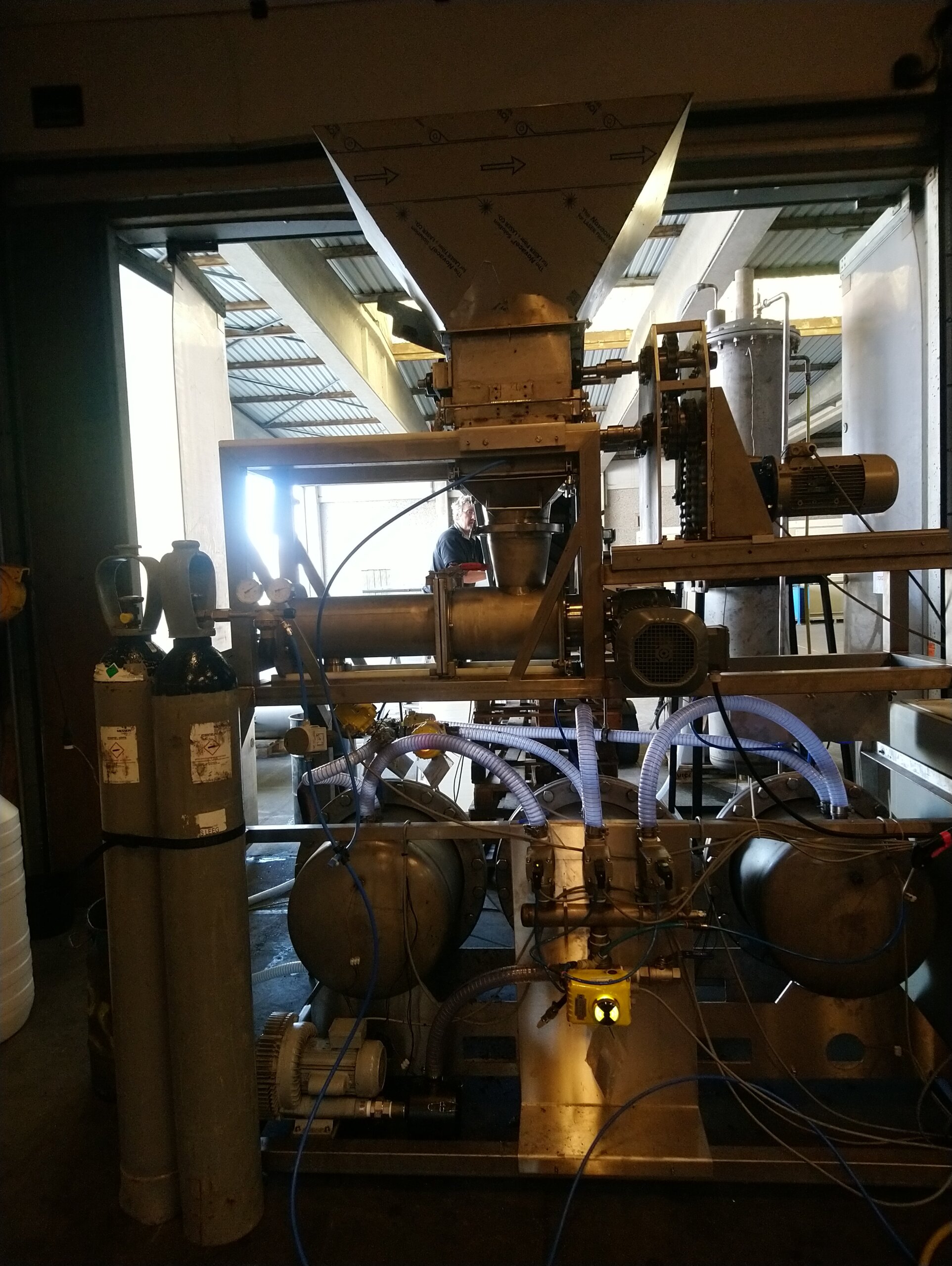

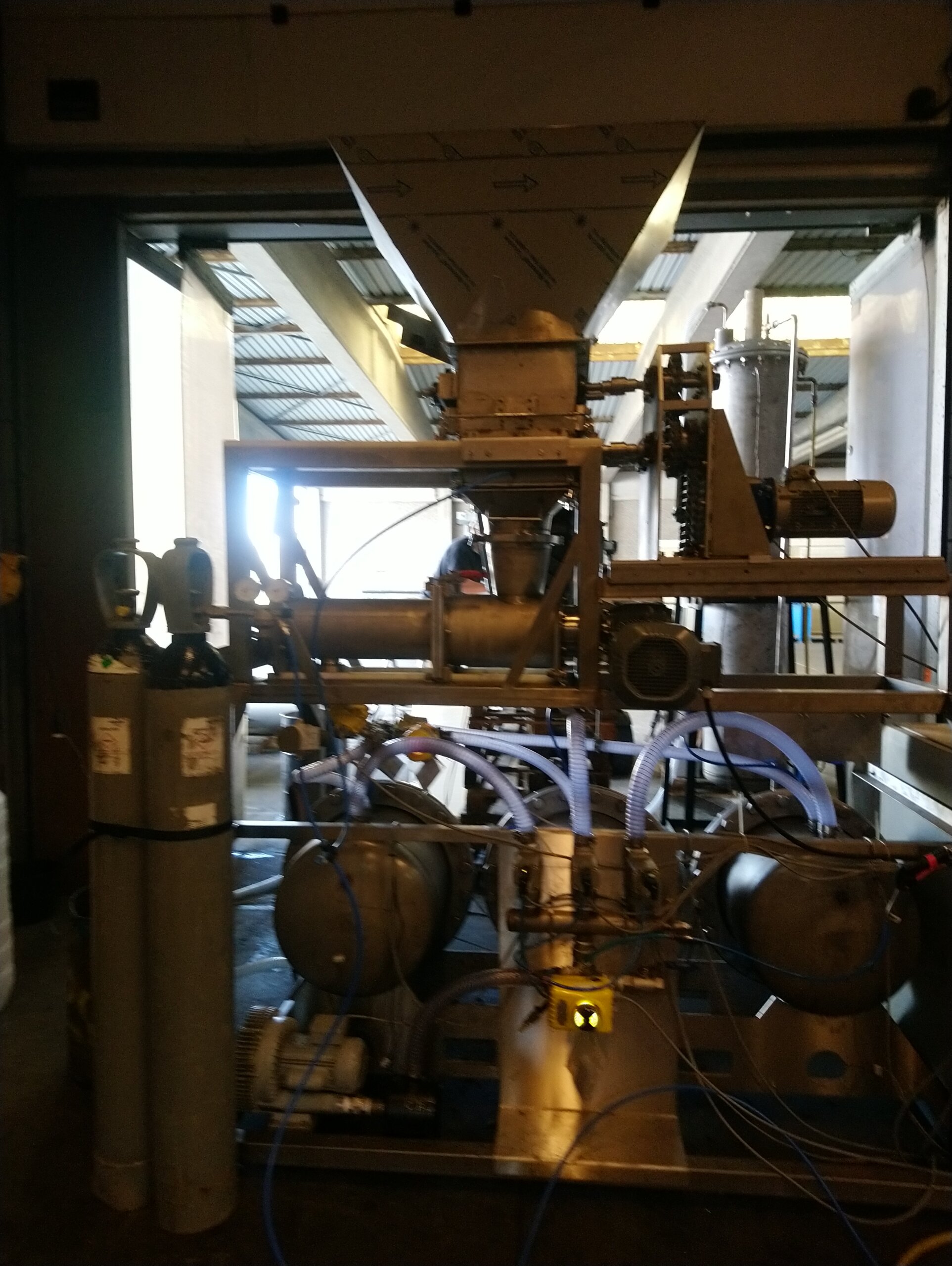

Over the years we have expanded our studio more and more, so that we can supply the most diverse needs.

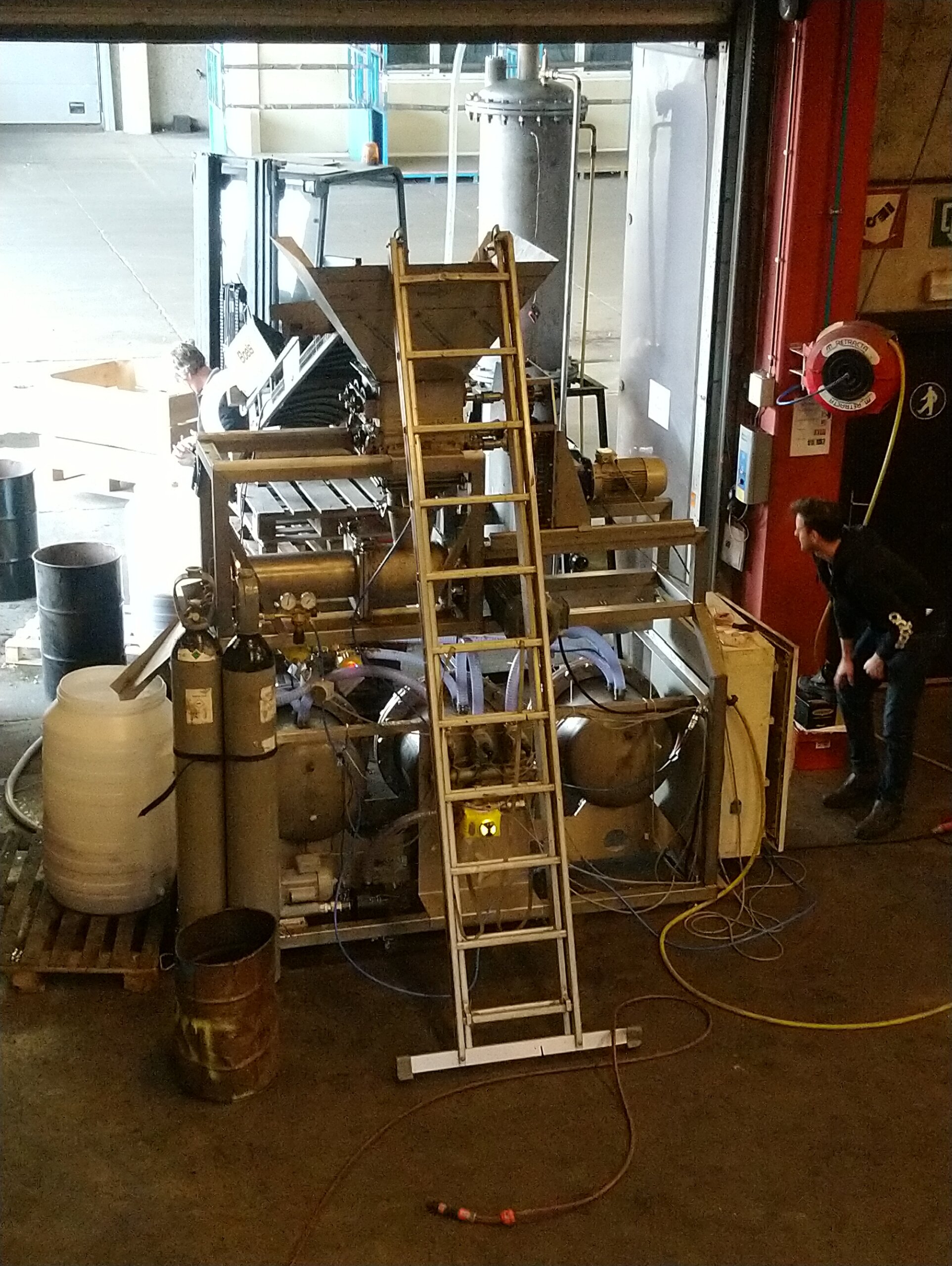

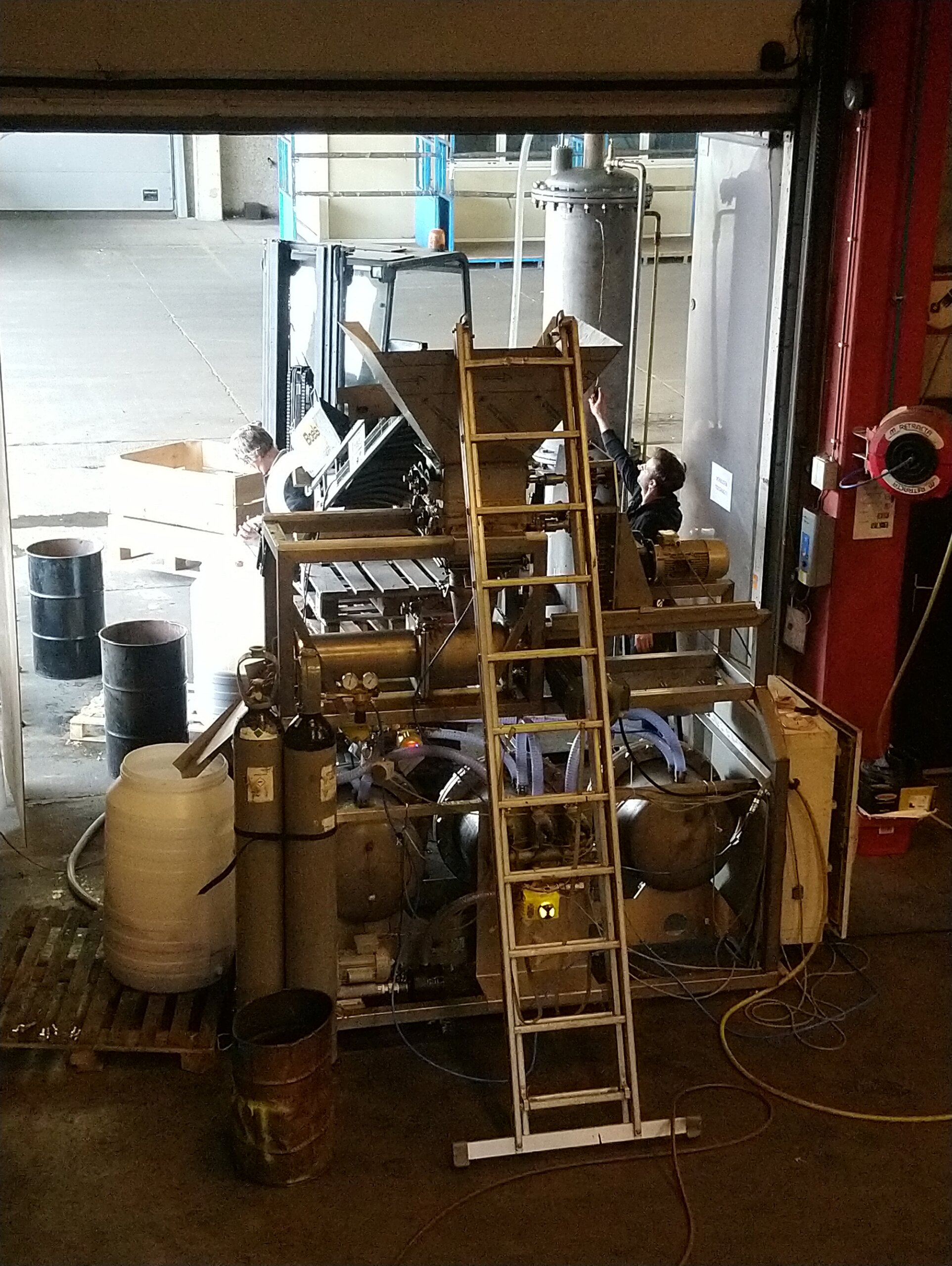

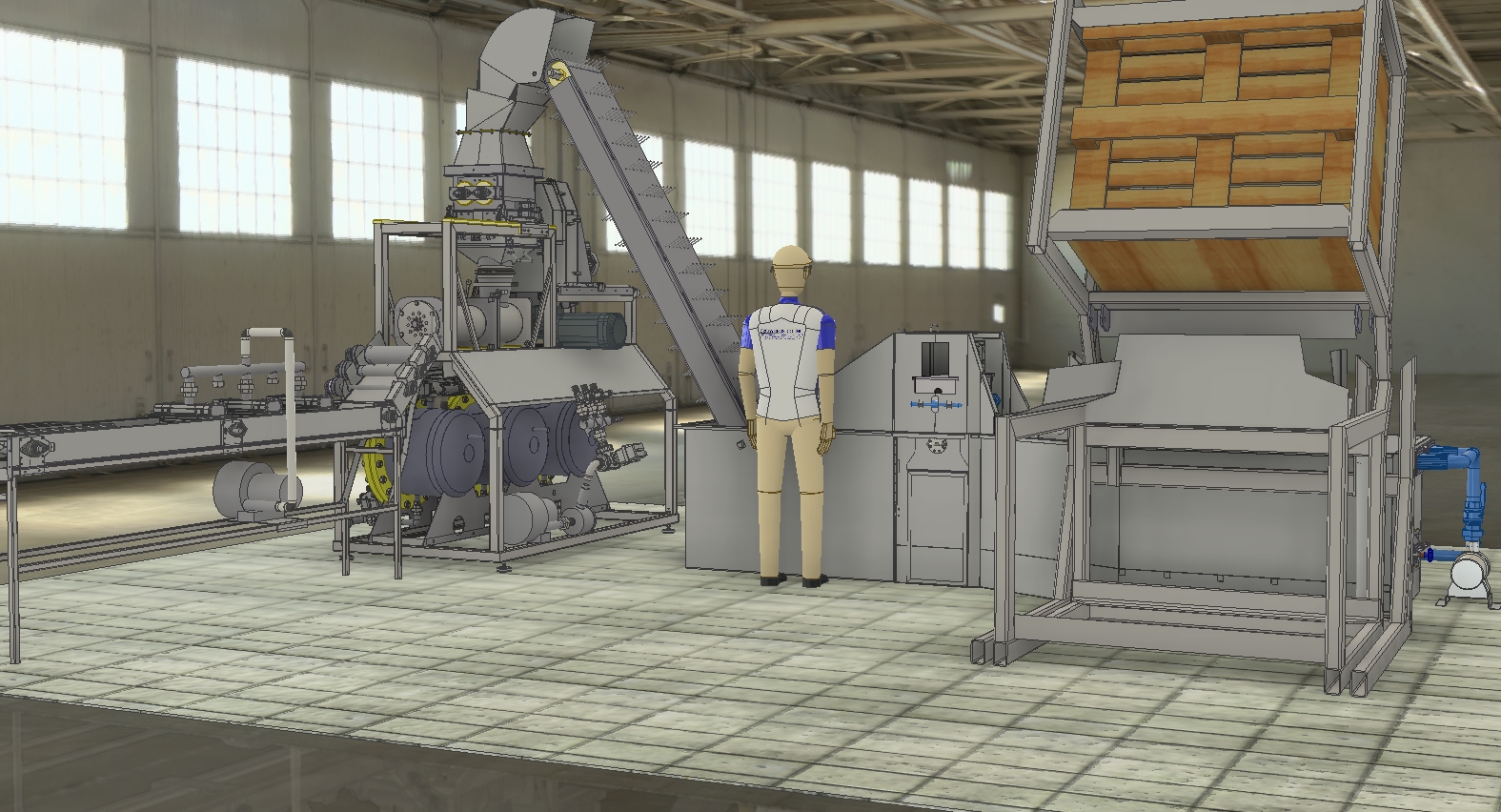

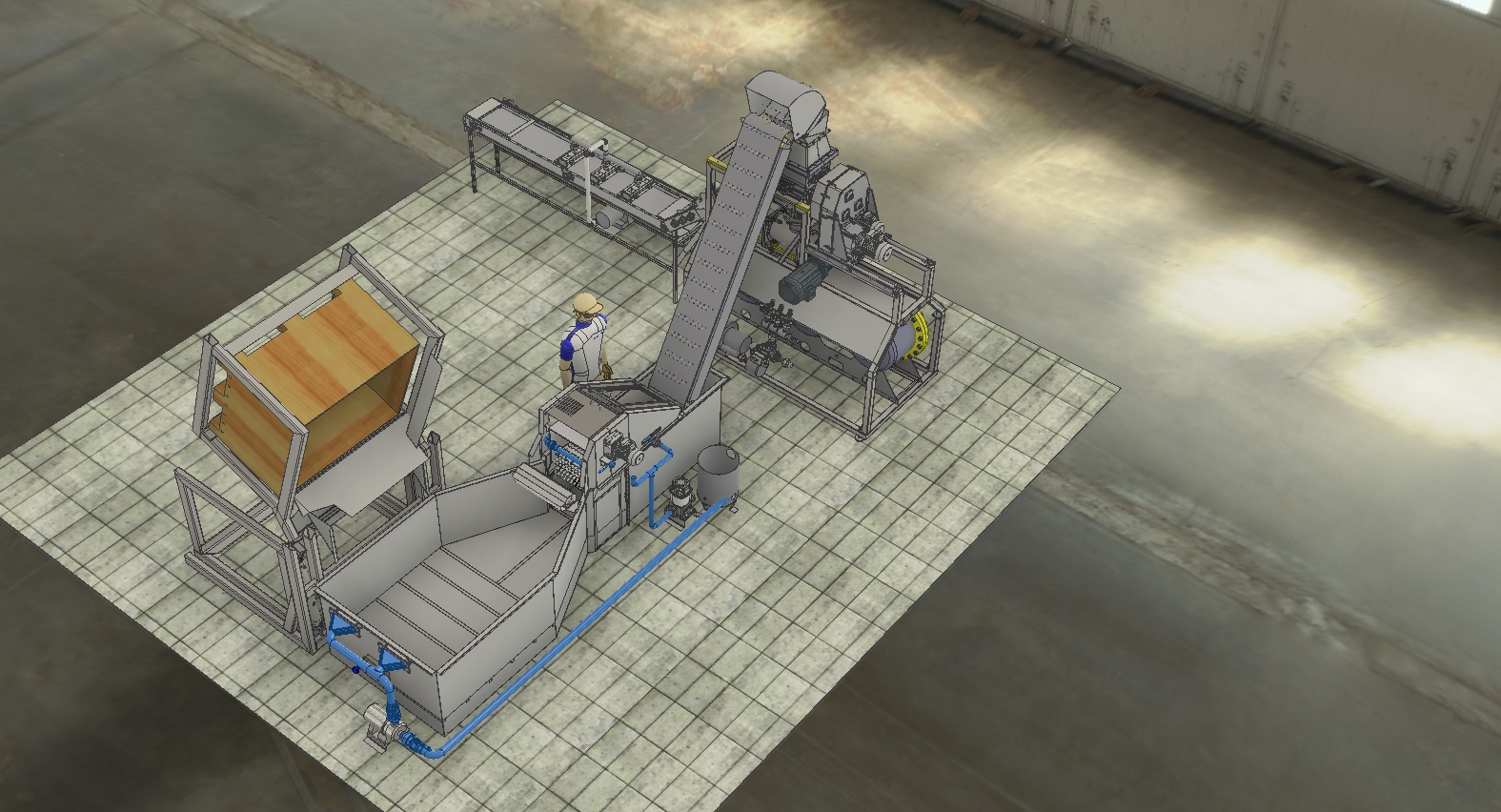

Your technicians

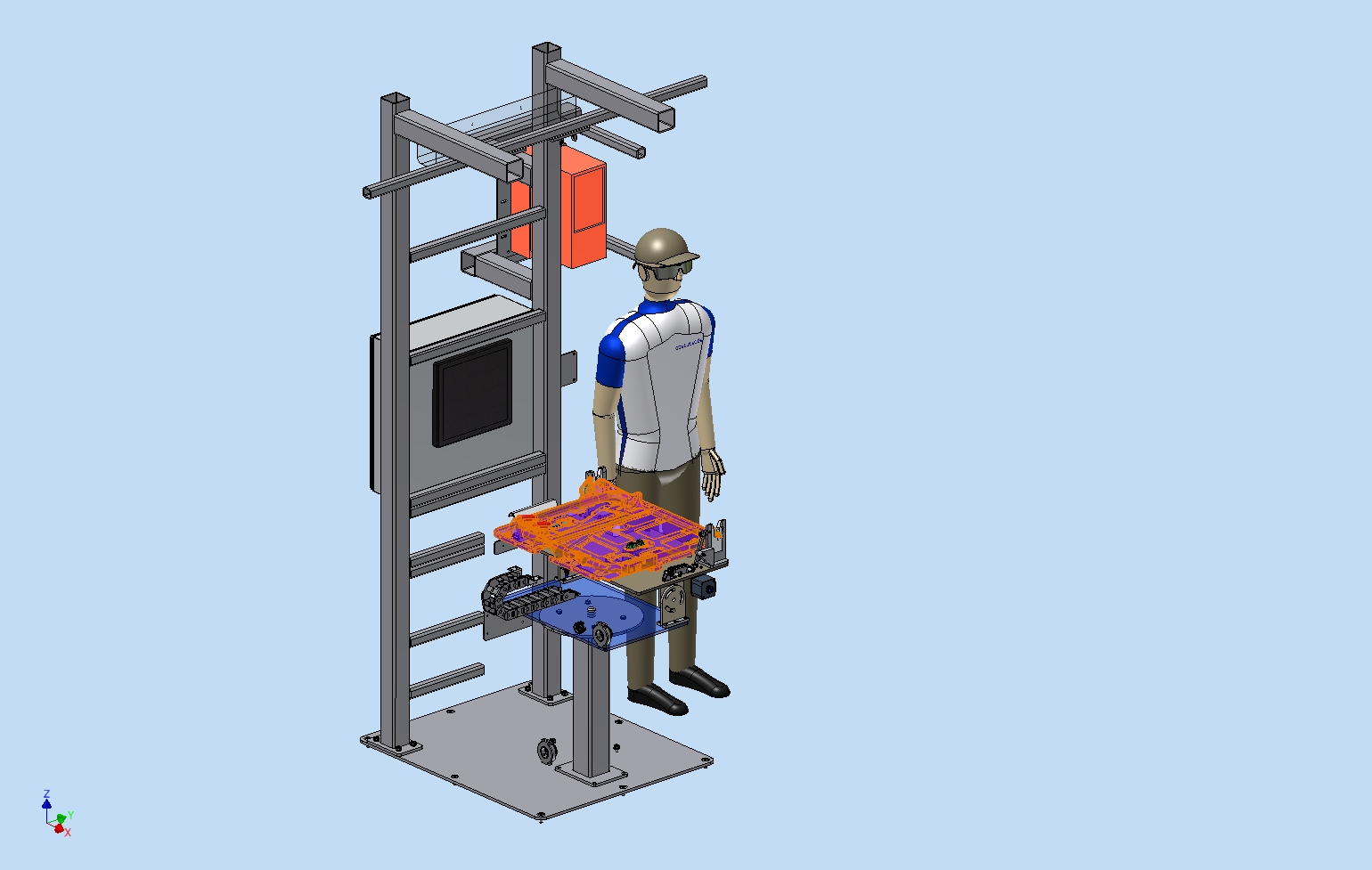

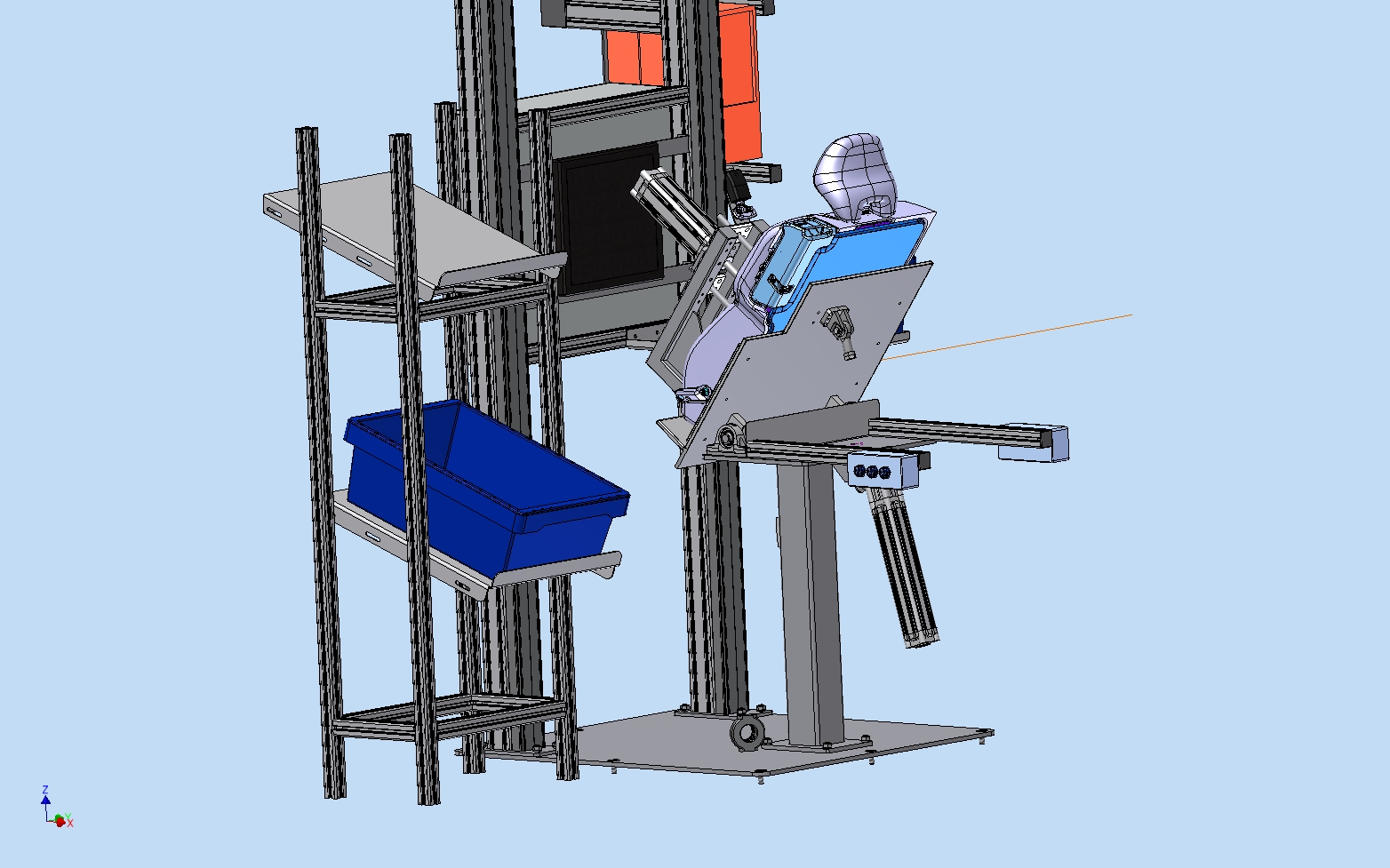

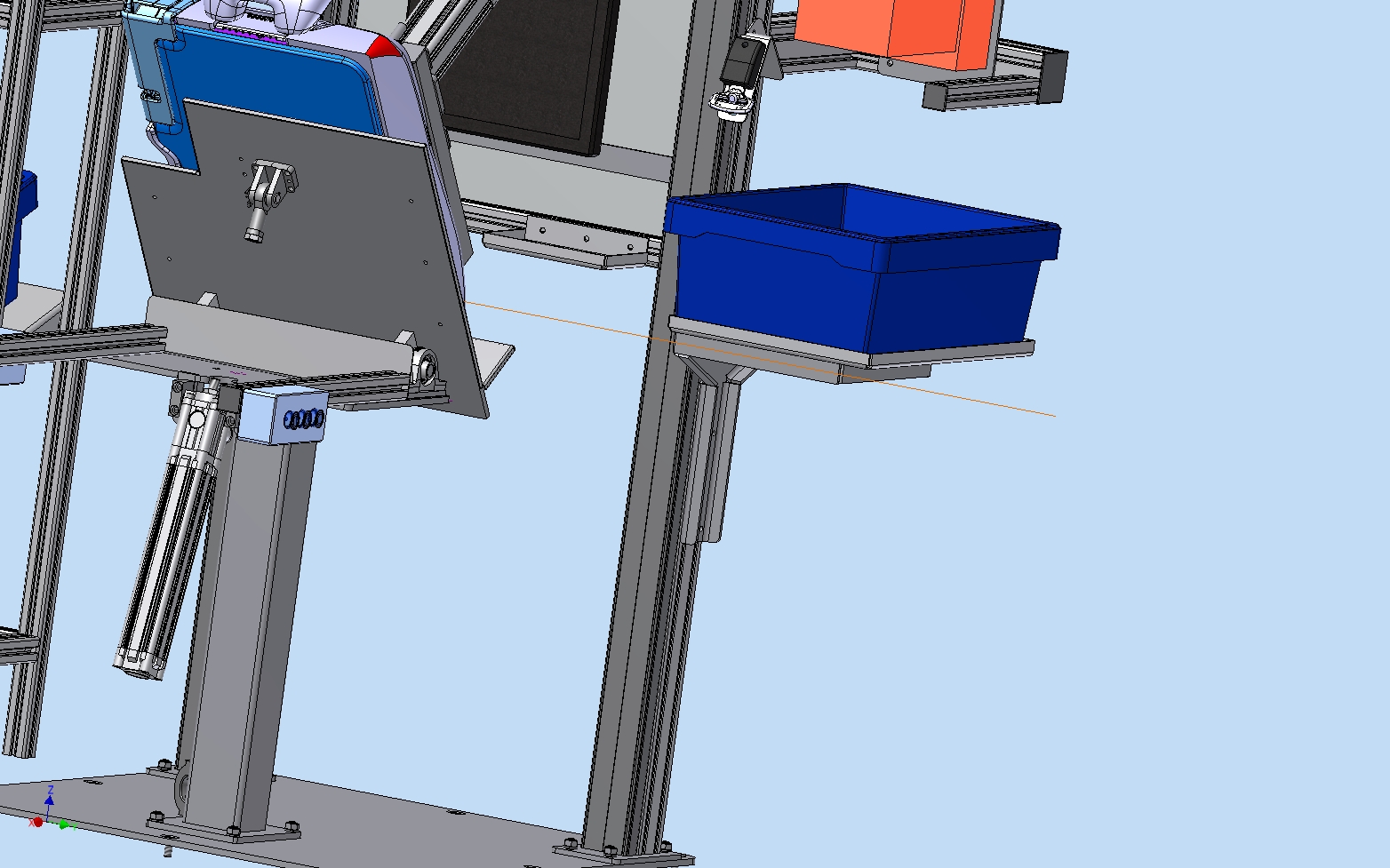

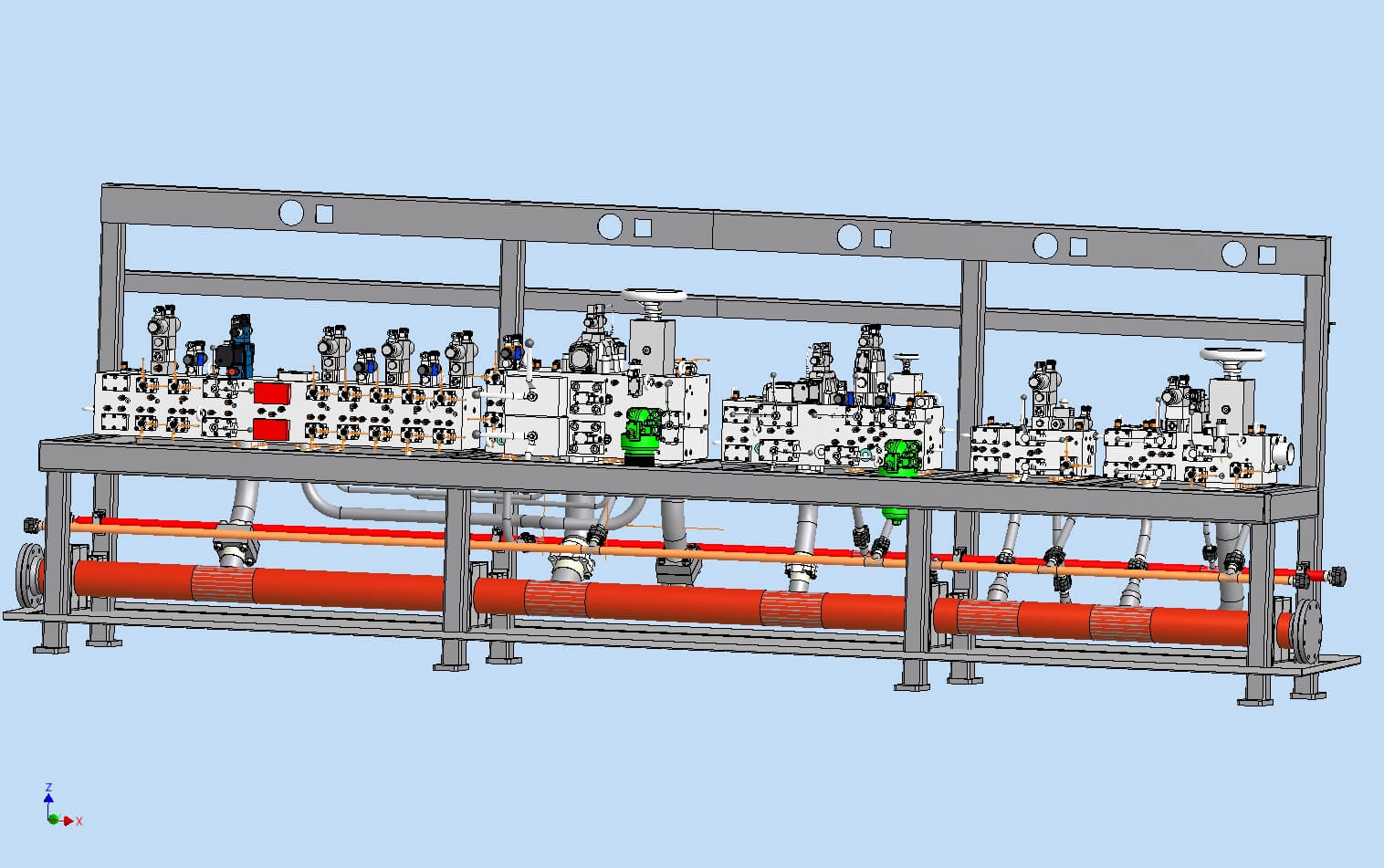

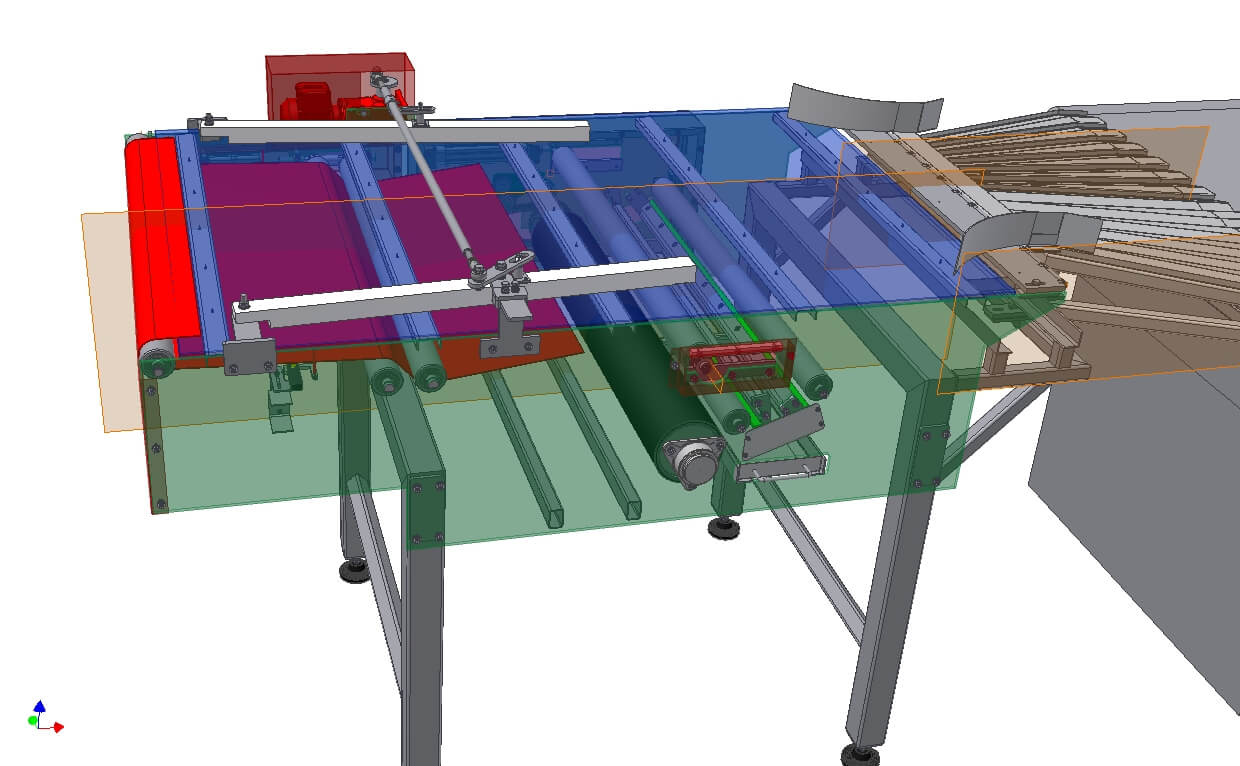

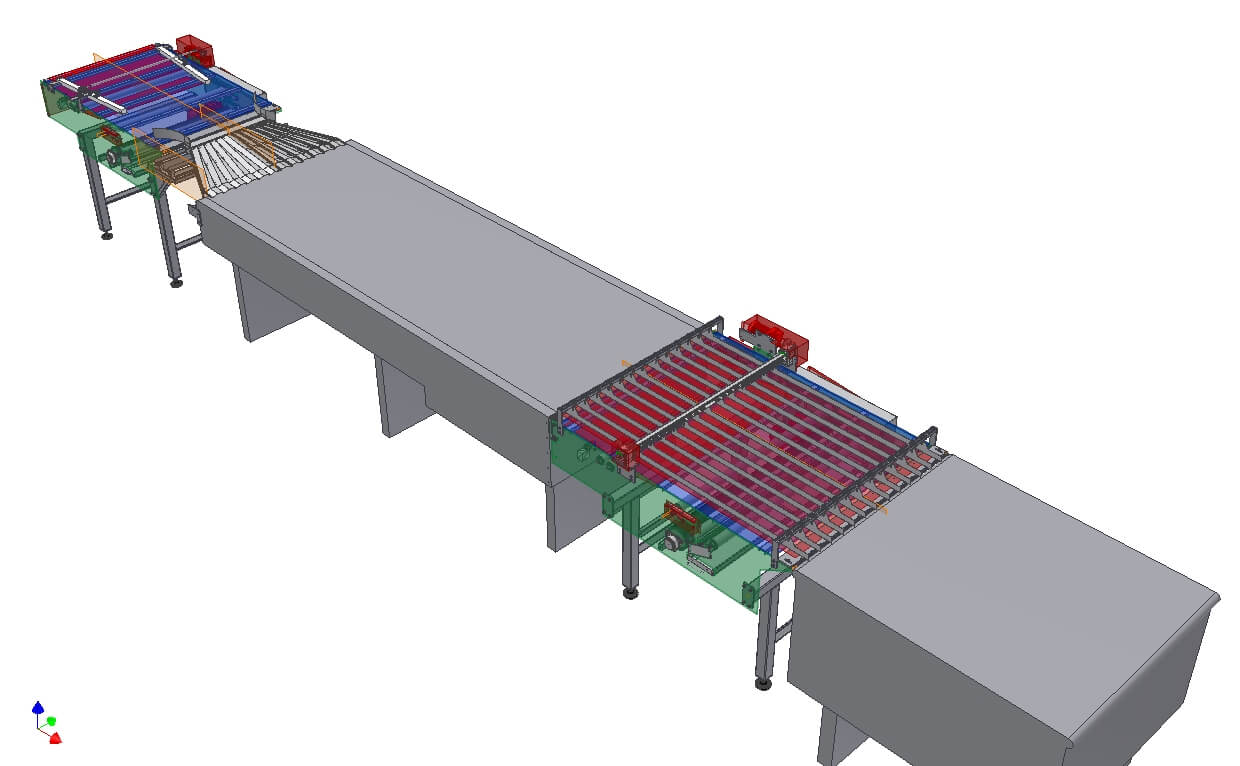

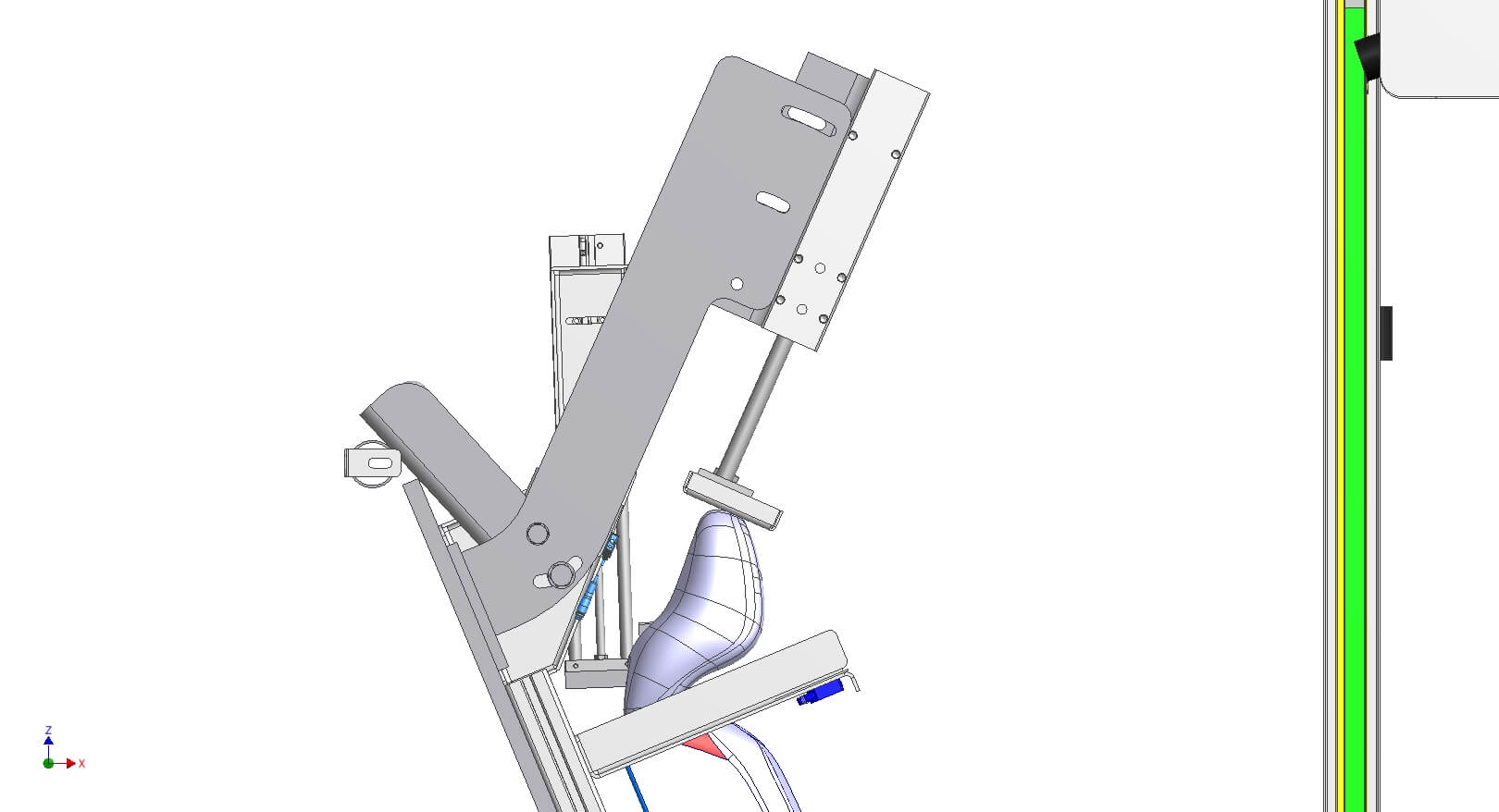

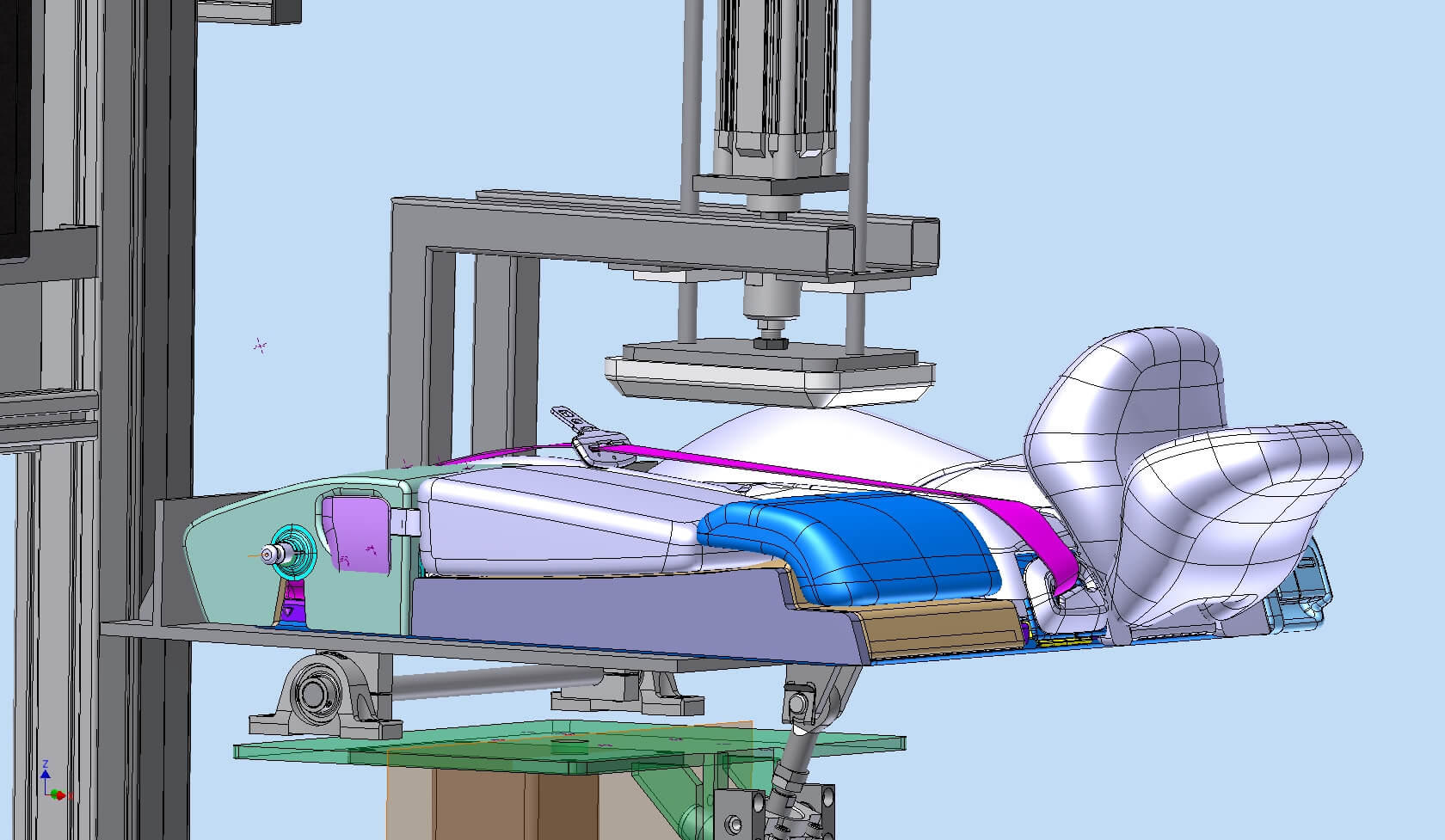

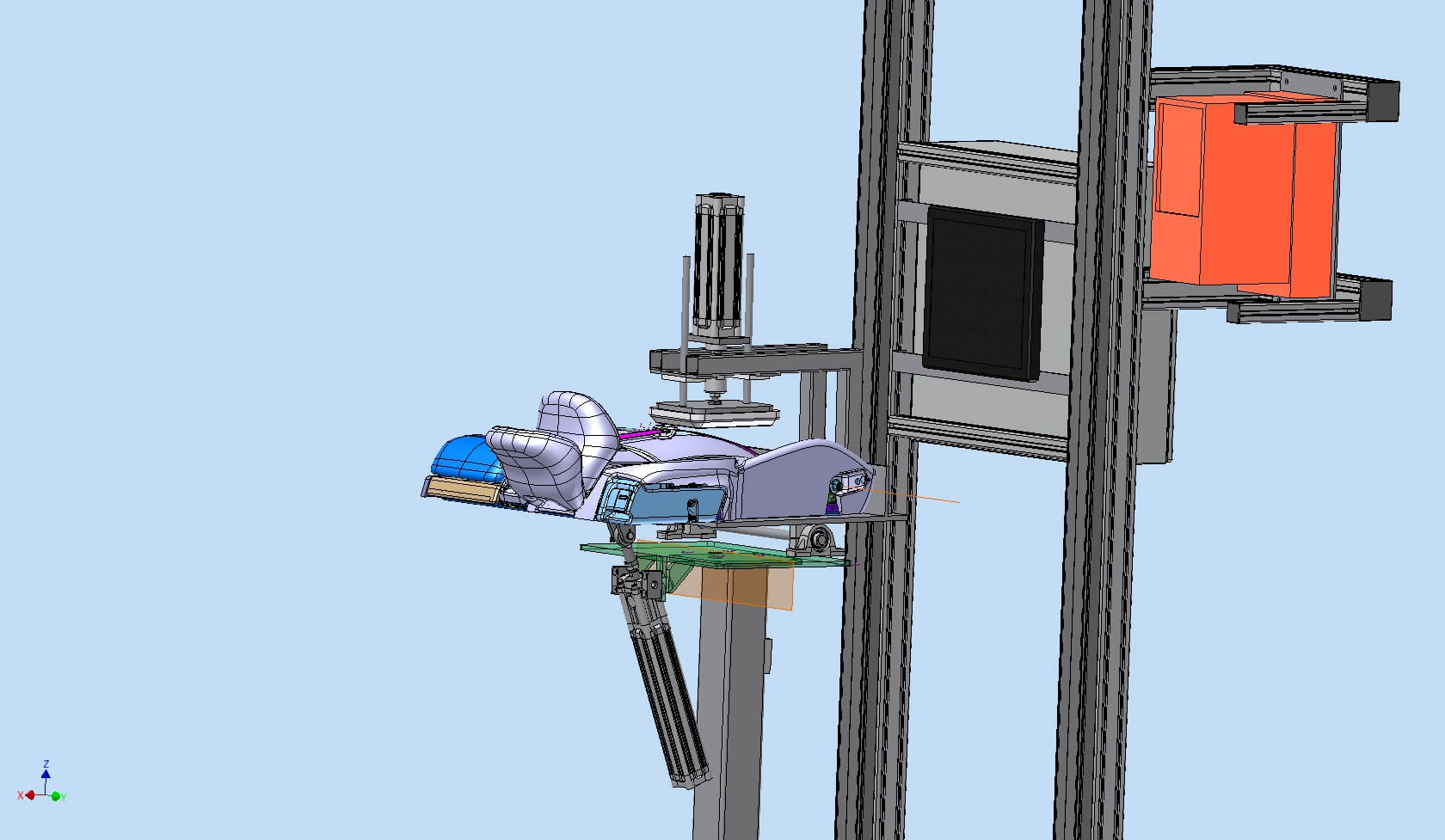

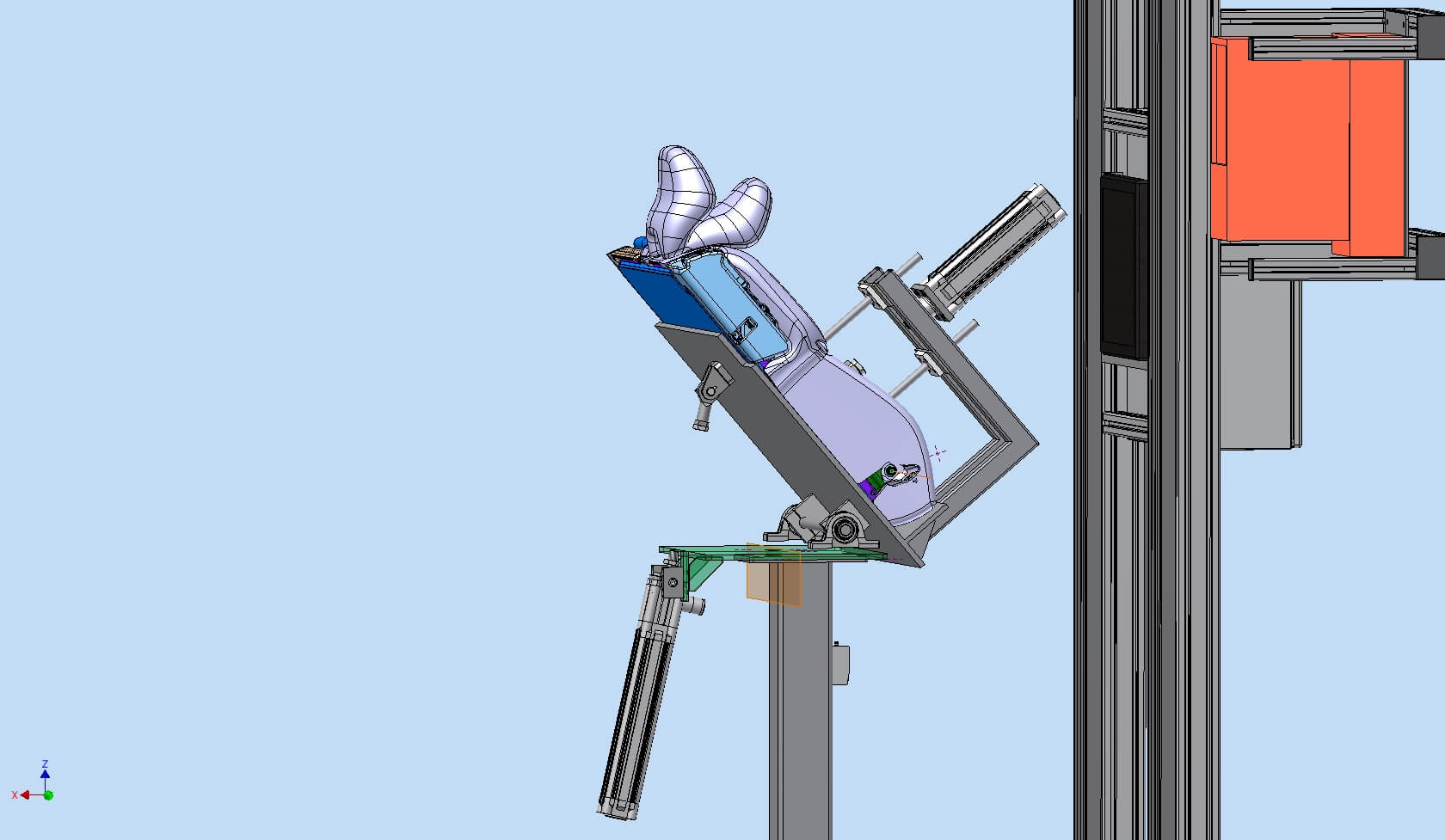

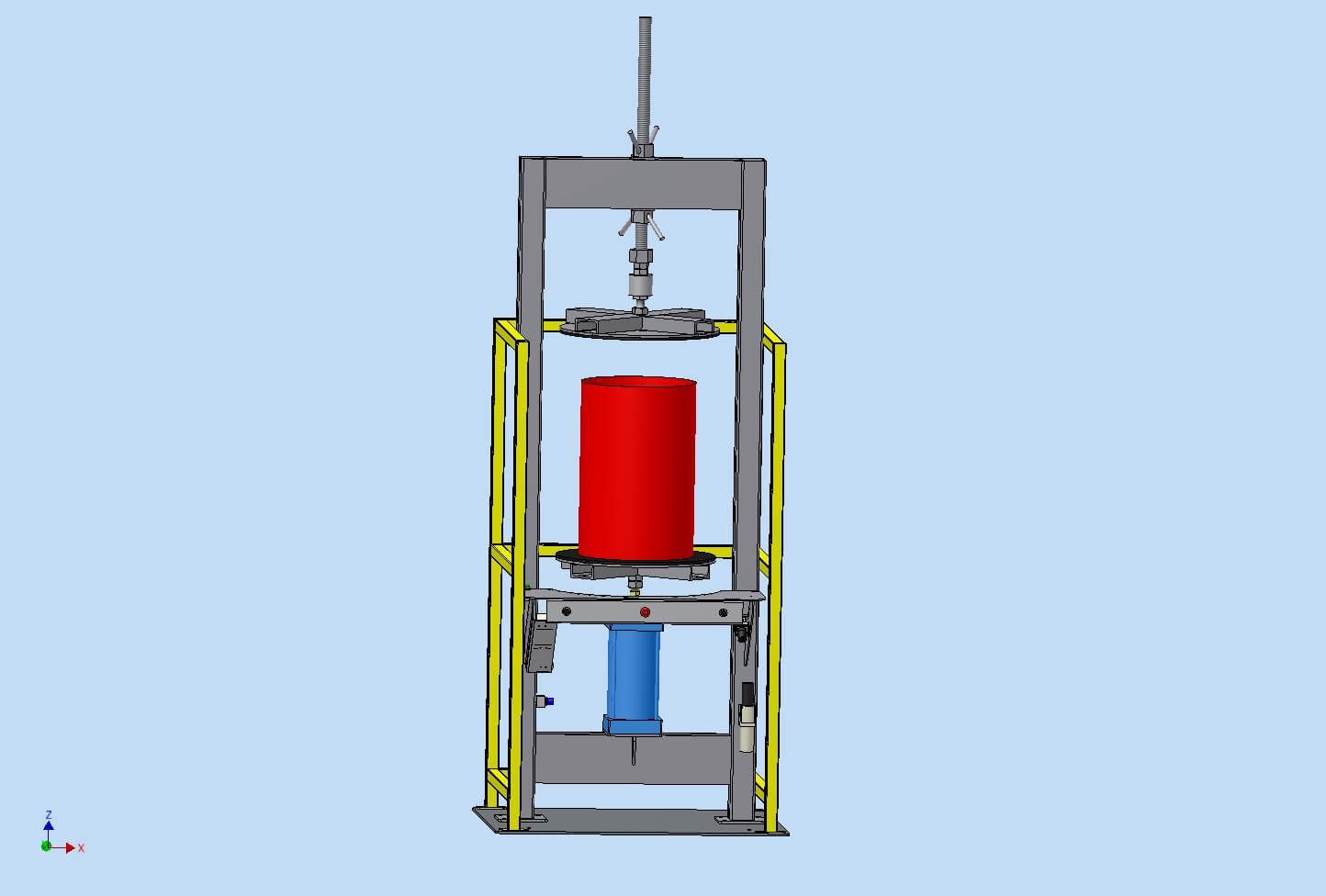

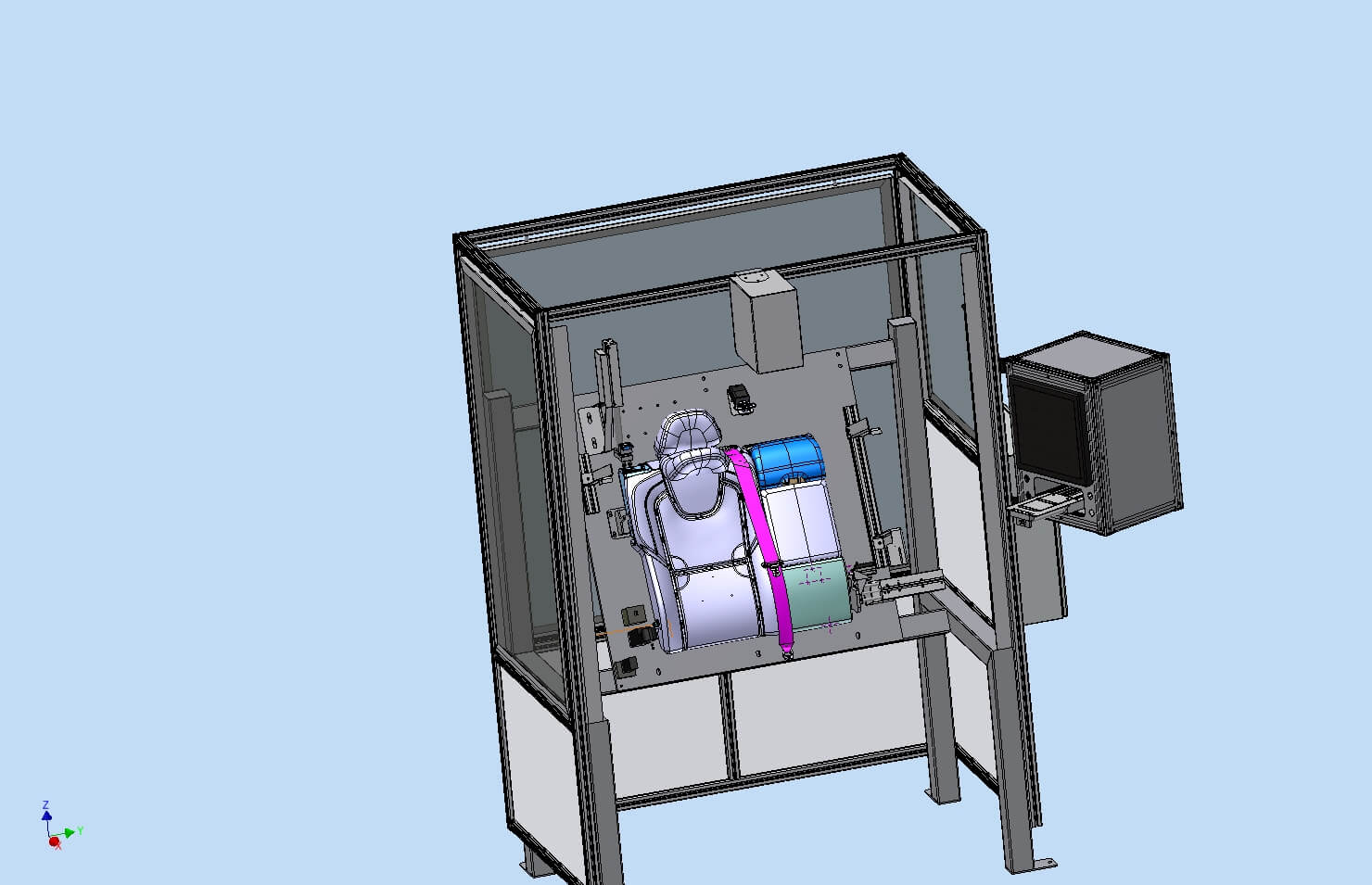

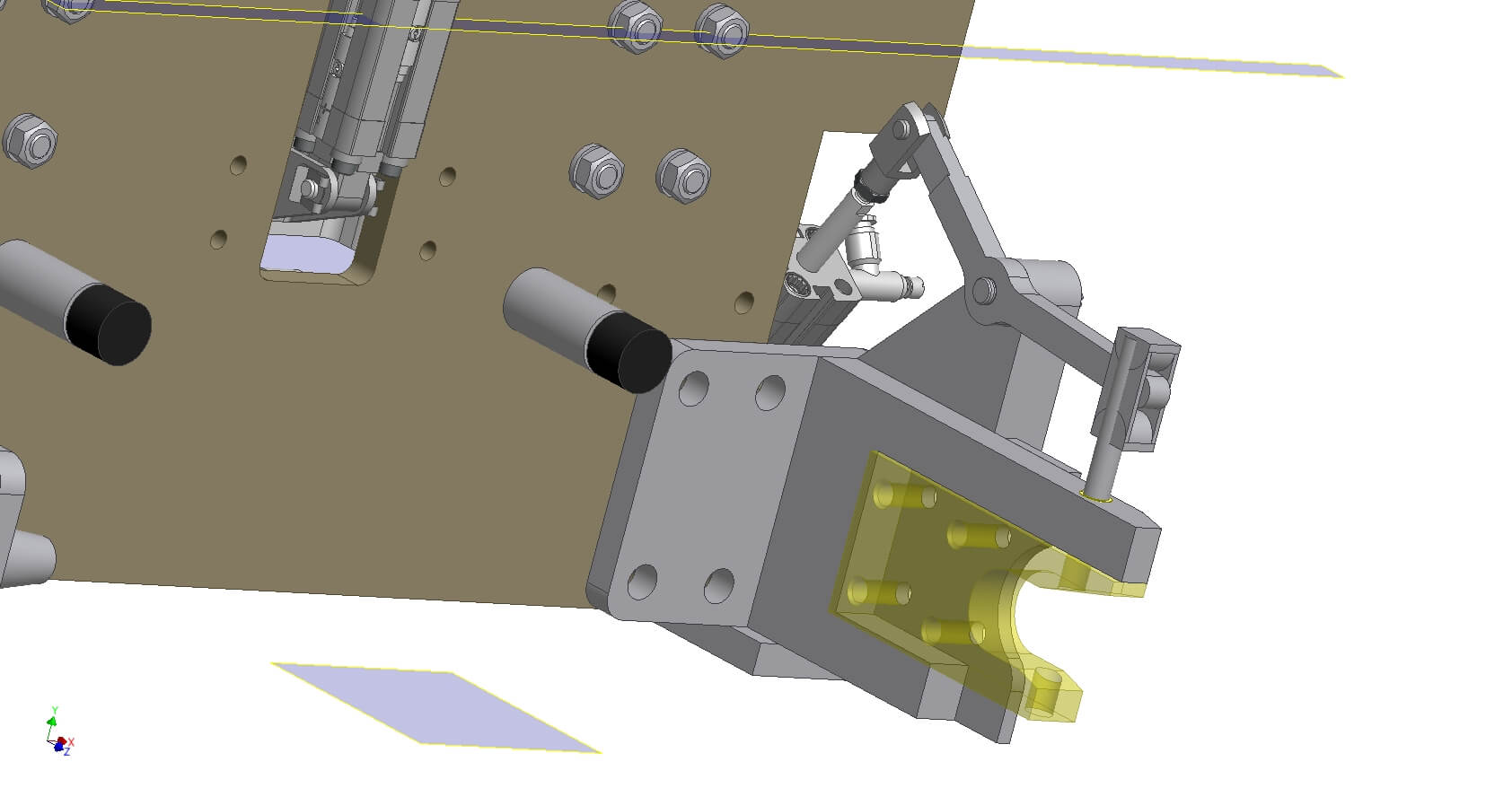

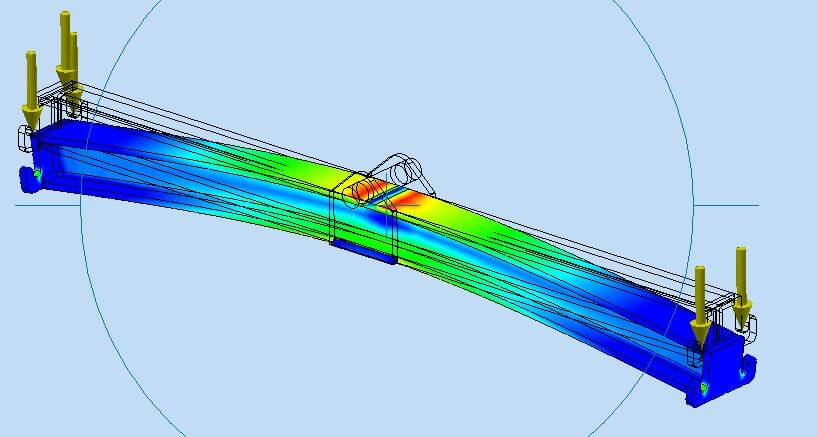

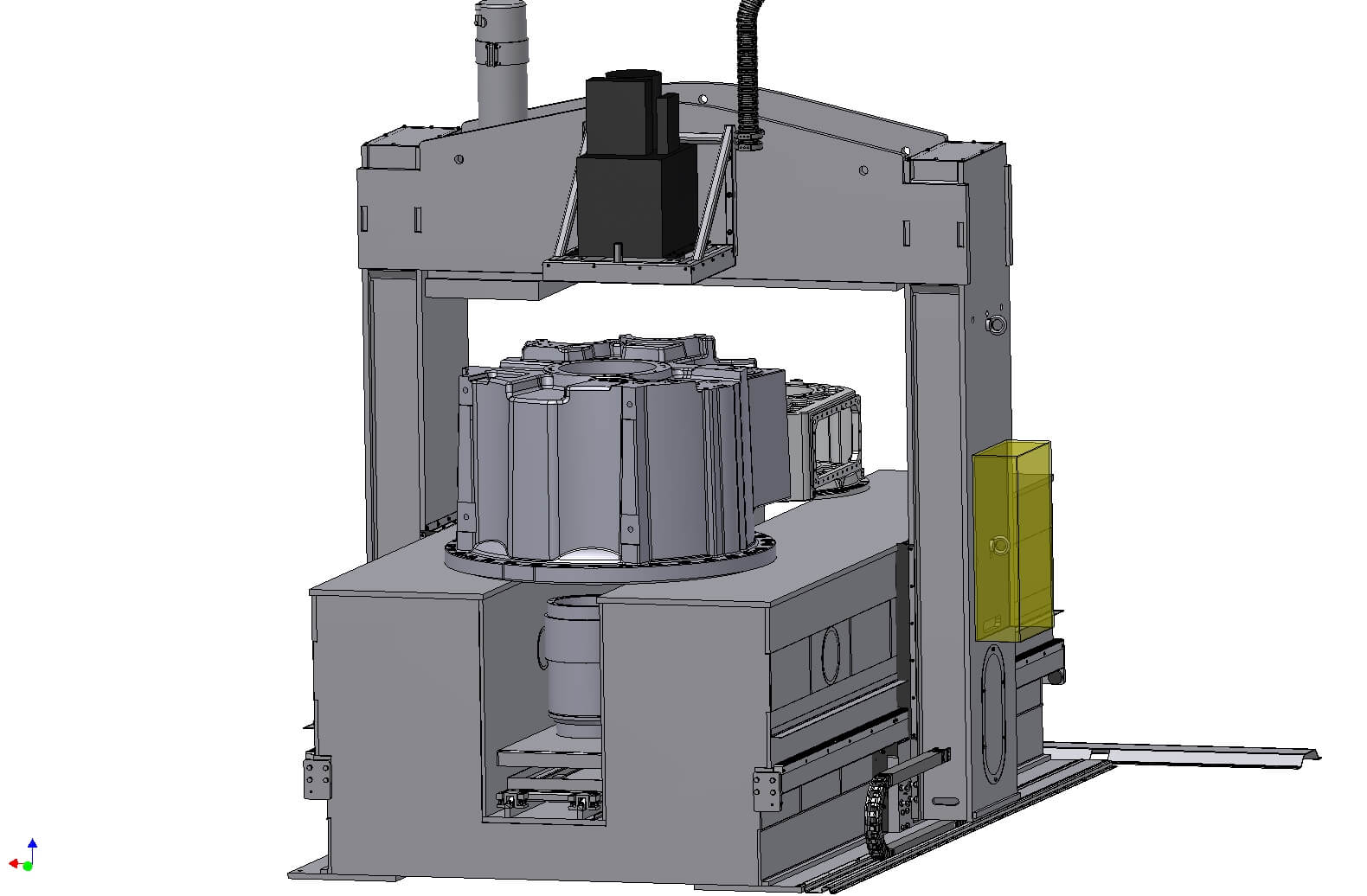

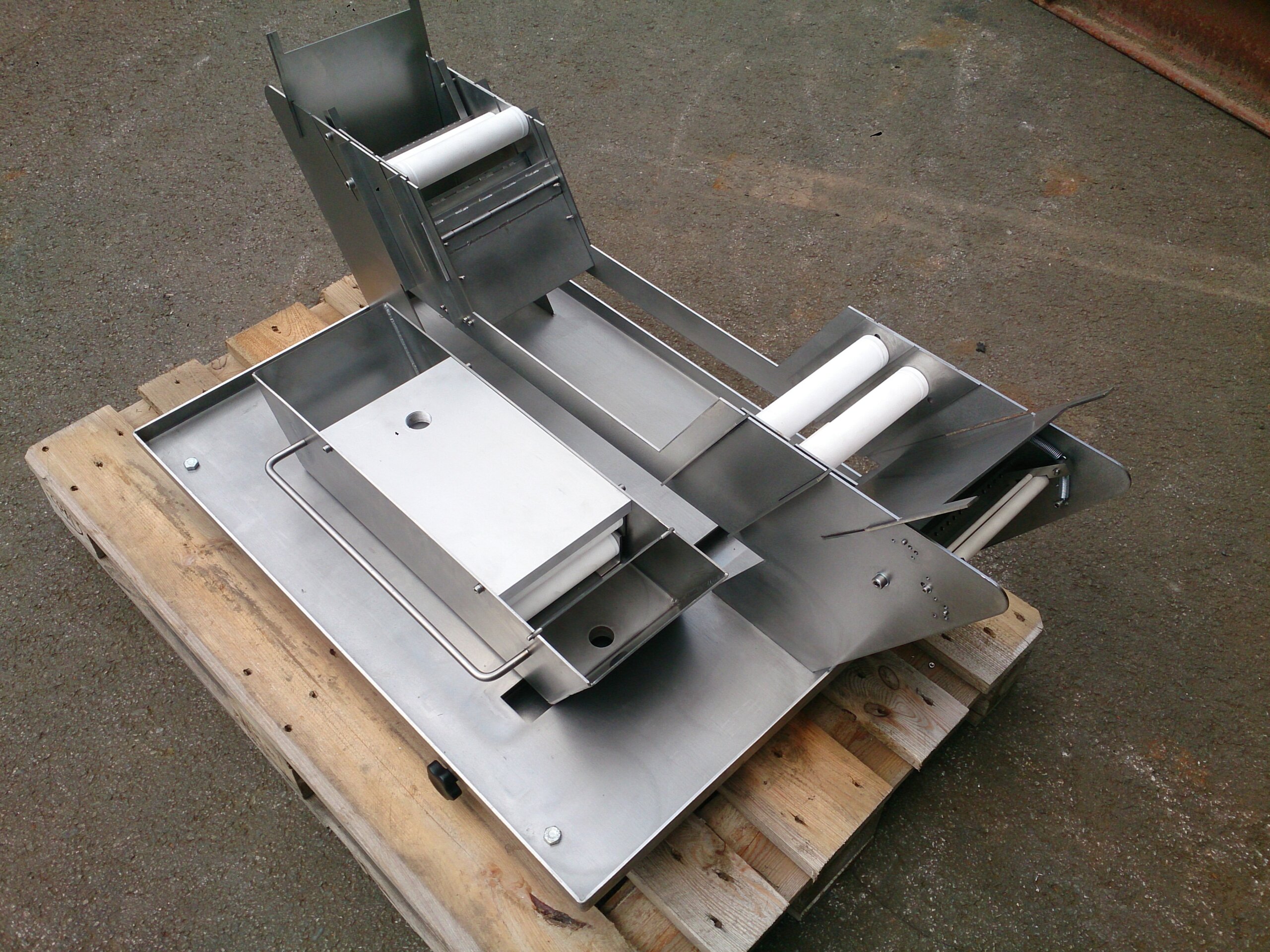

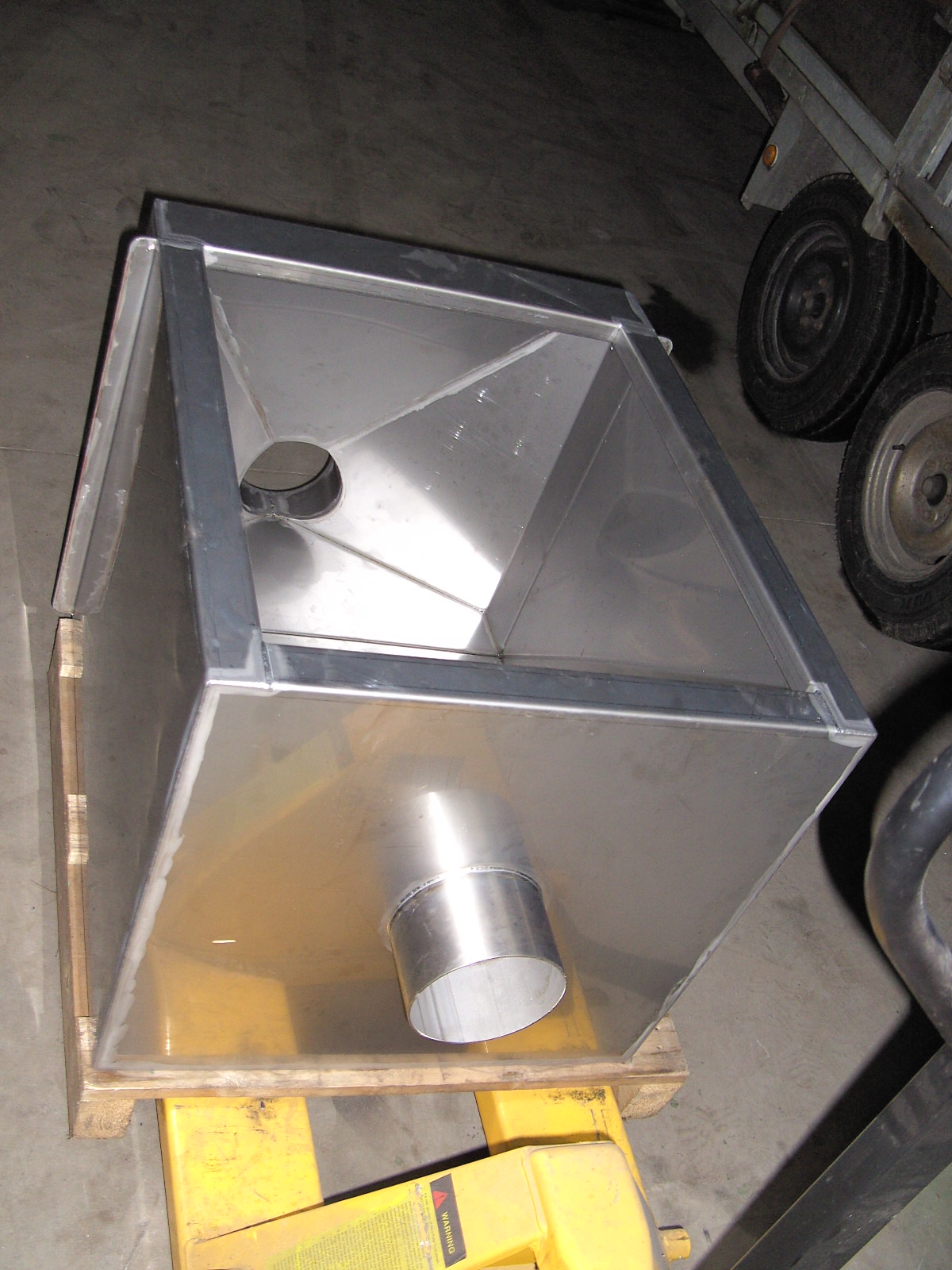

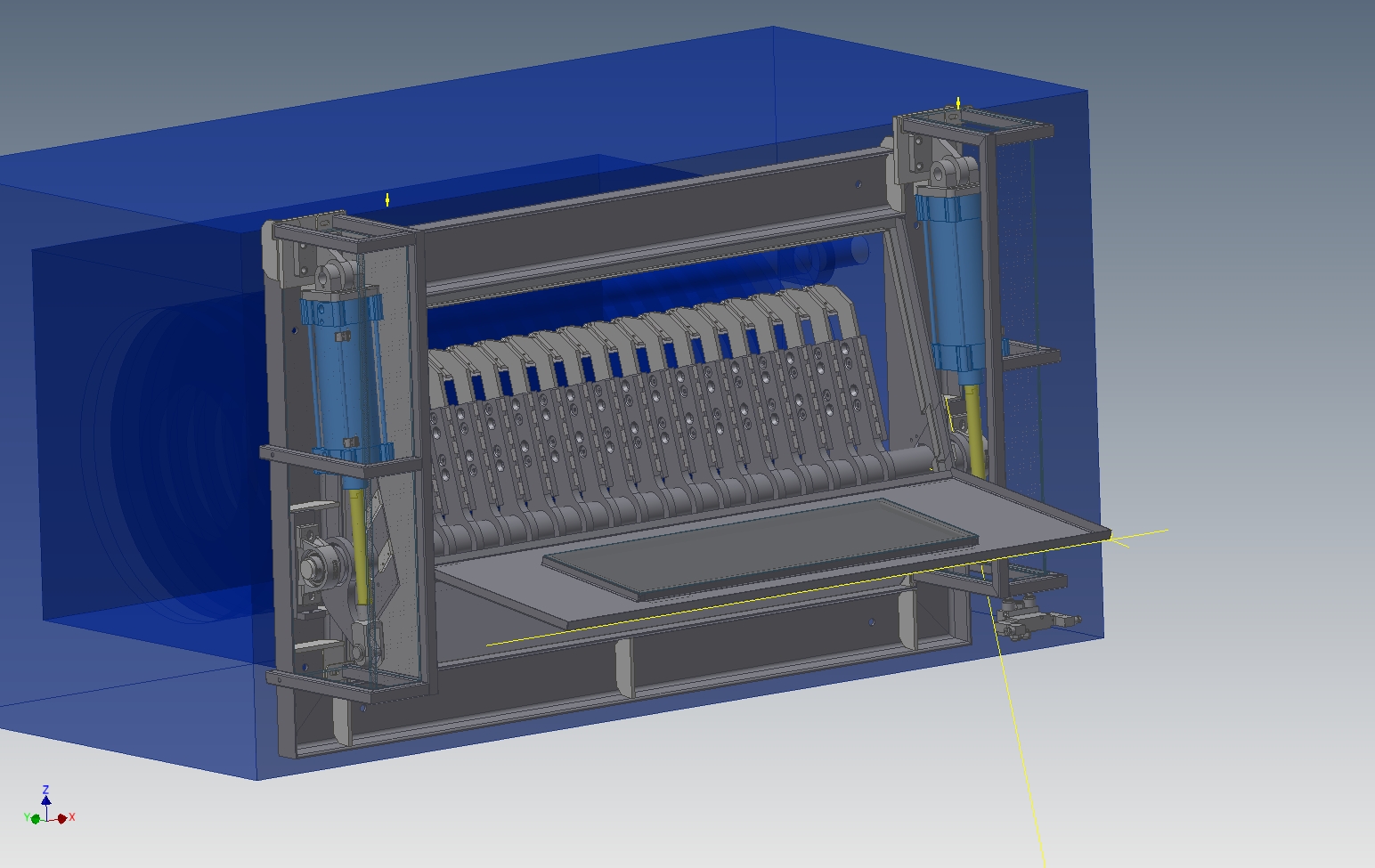

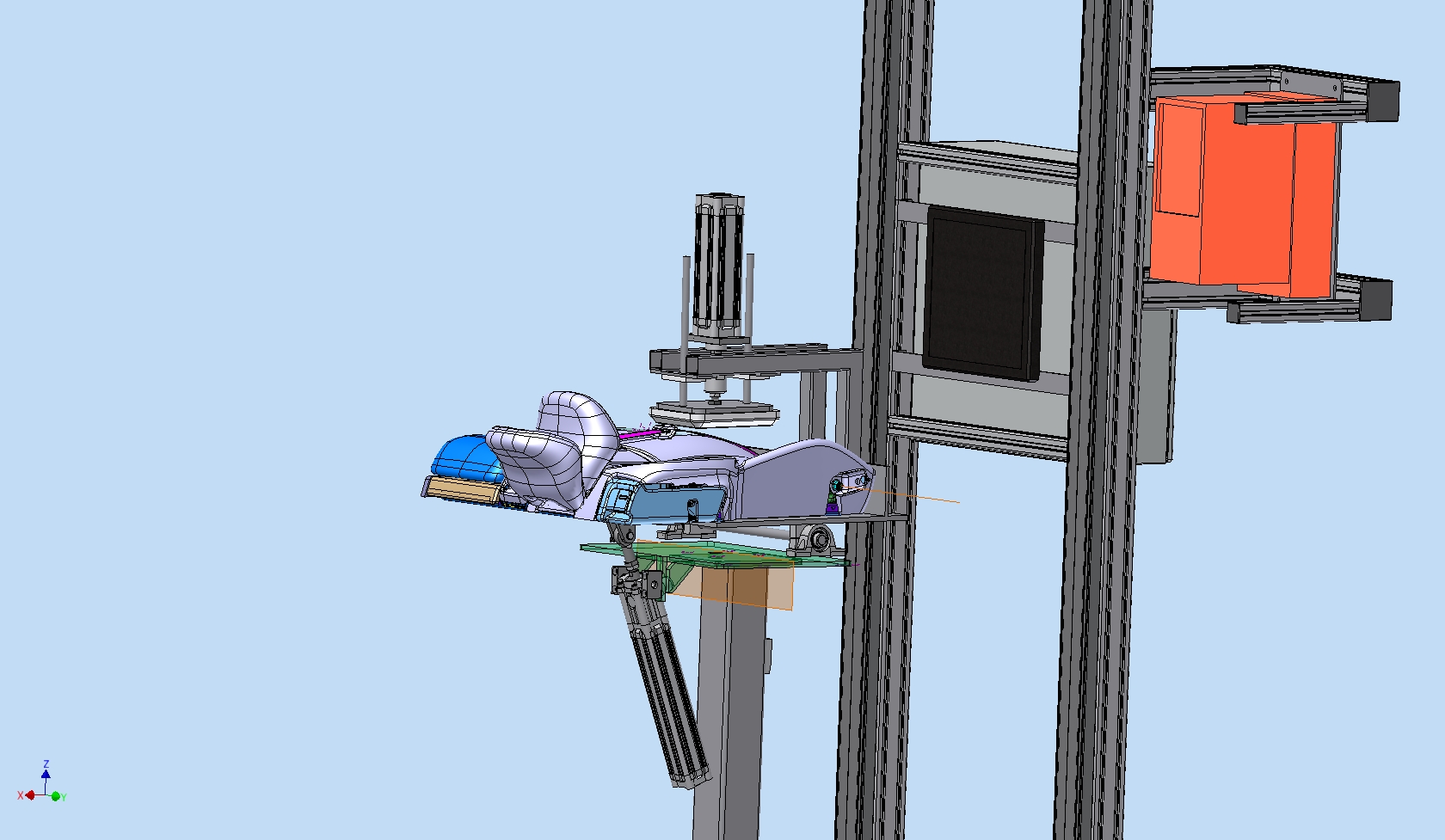

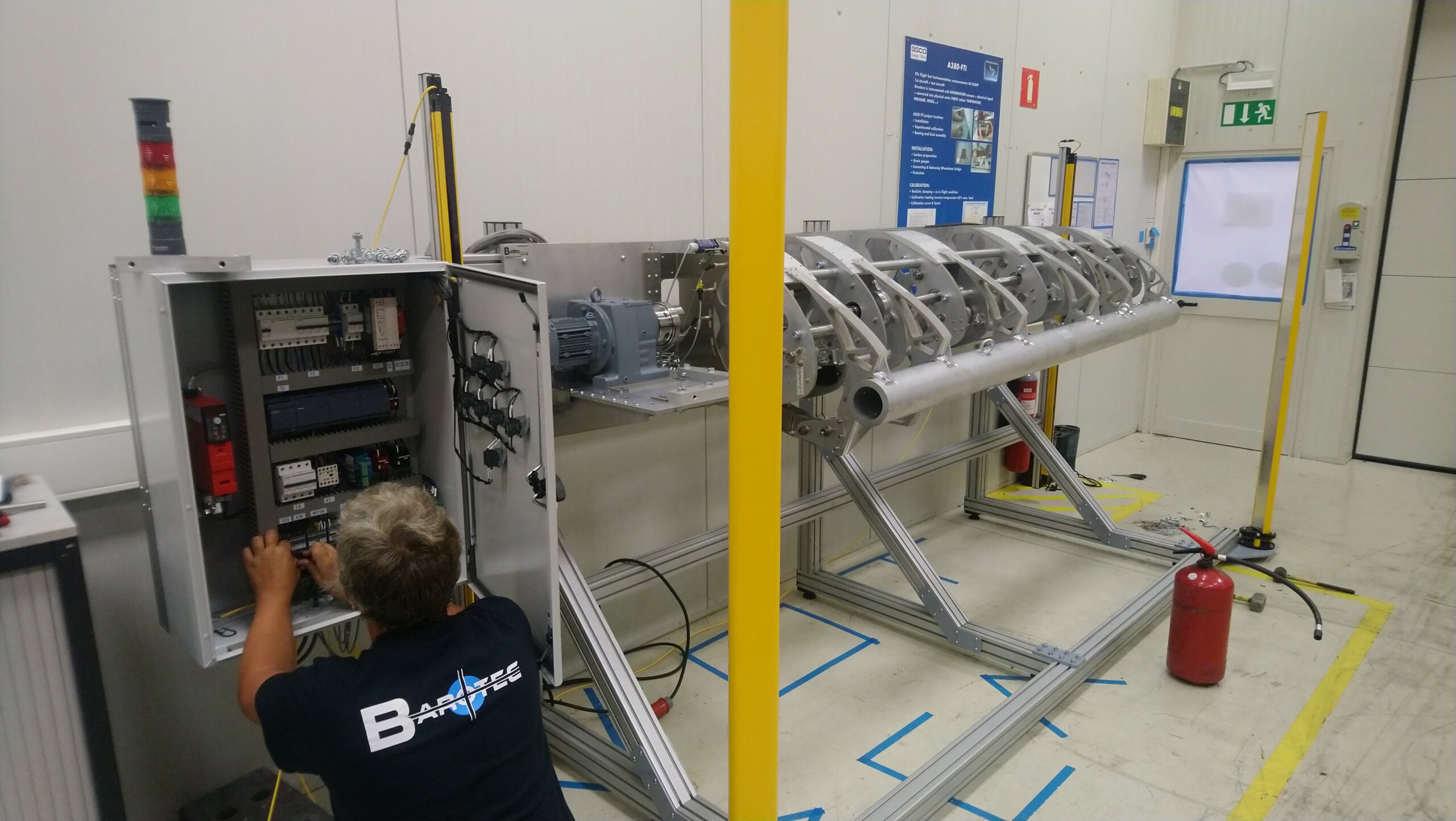

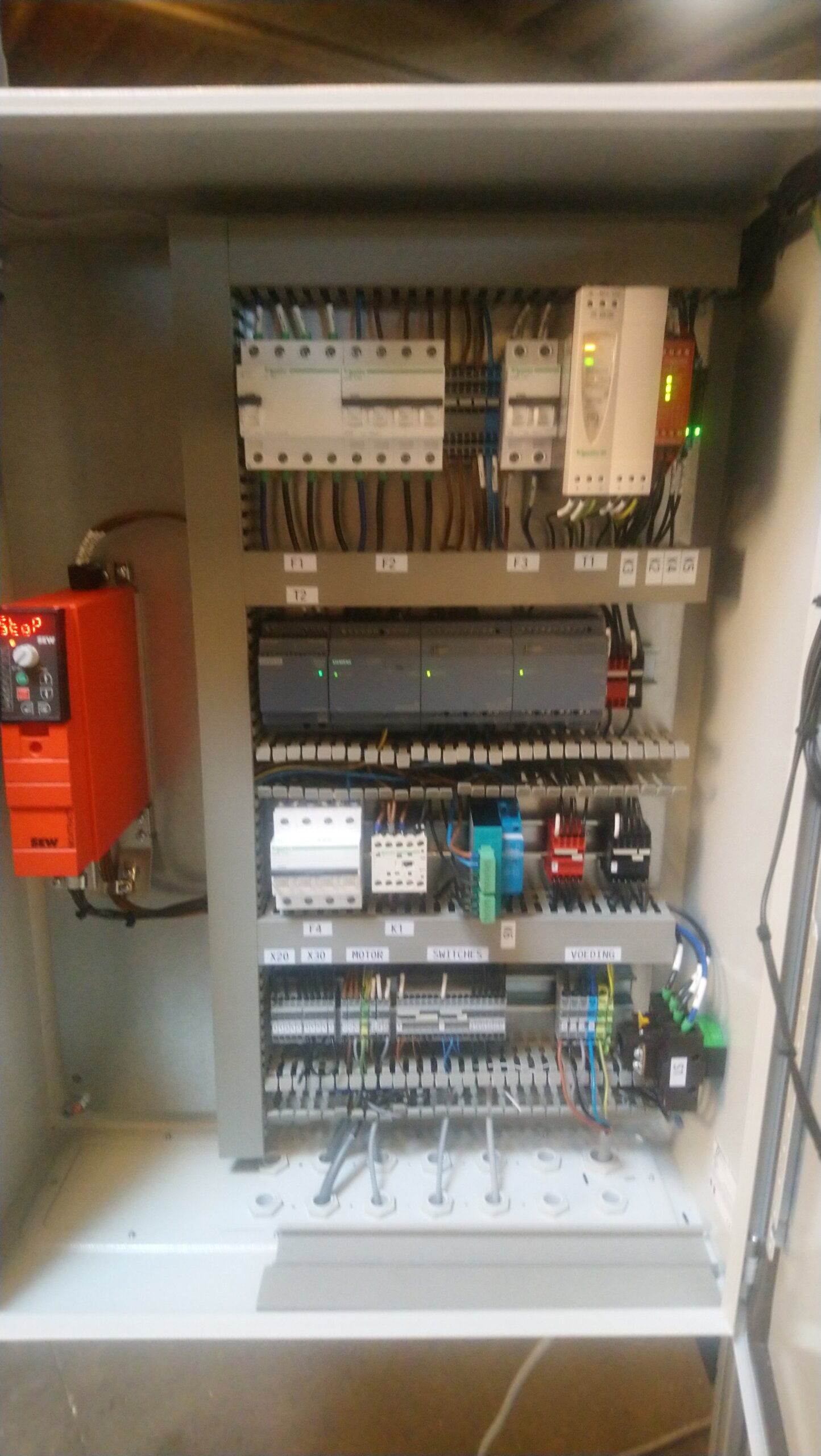

The engineering team follows up the projects from A to Z. Drawing, submitting the drawing to the customer for approval, starting the project, checking and following up.

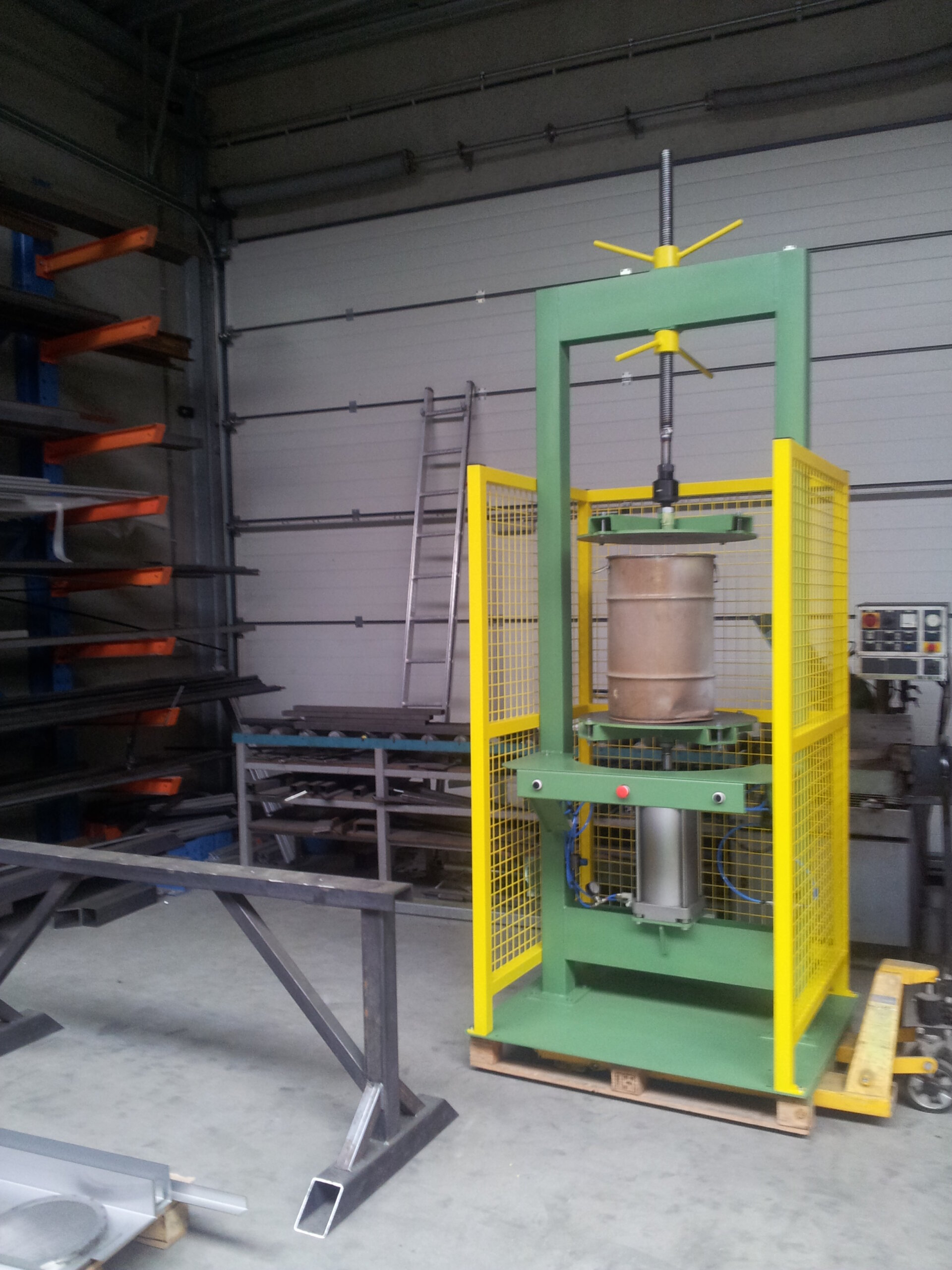

Our team of welders and mechanics take care of the execution:

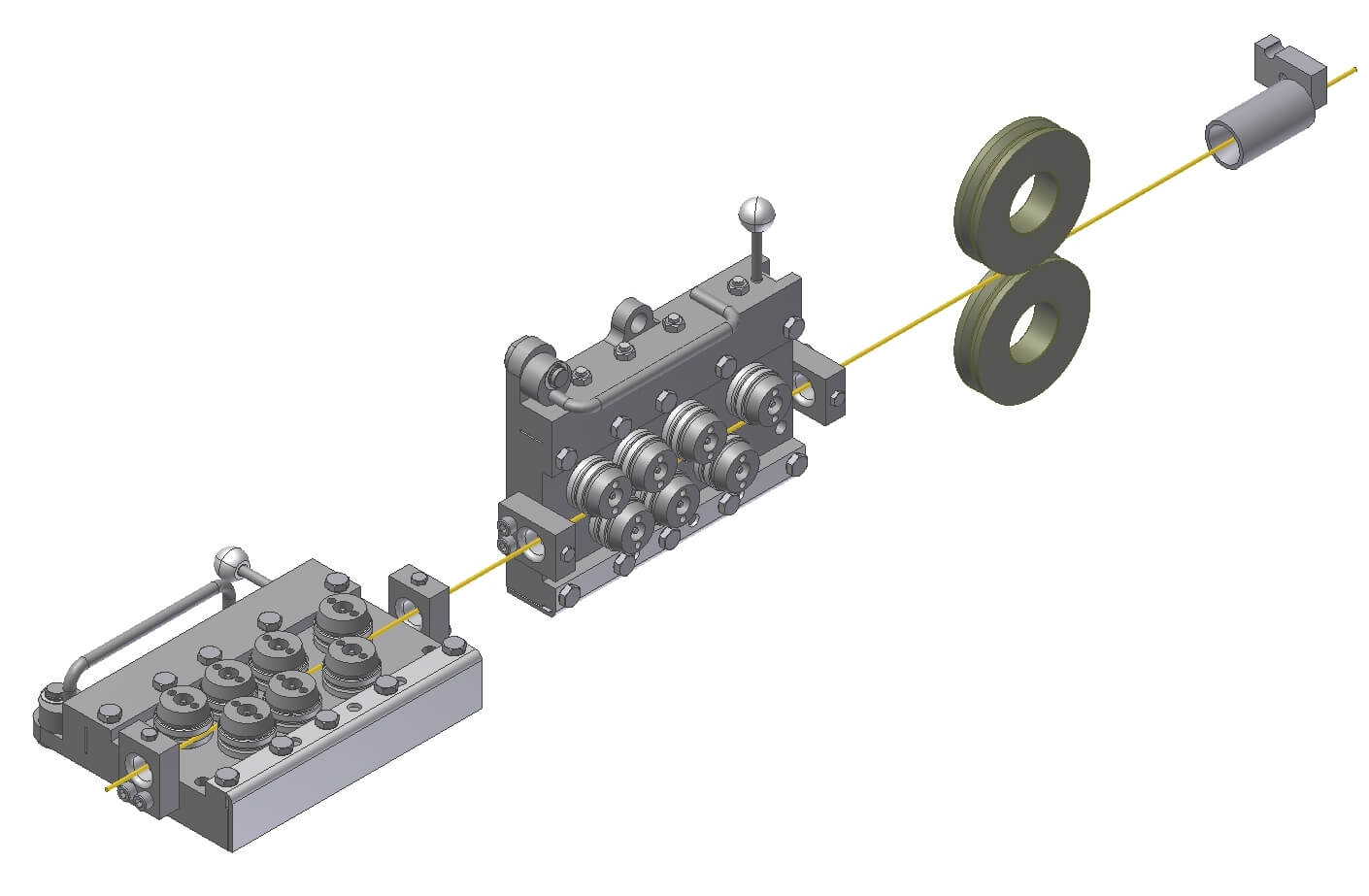

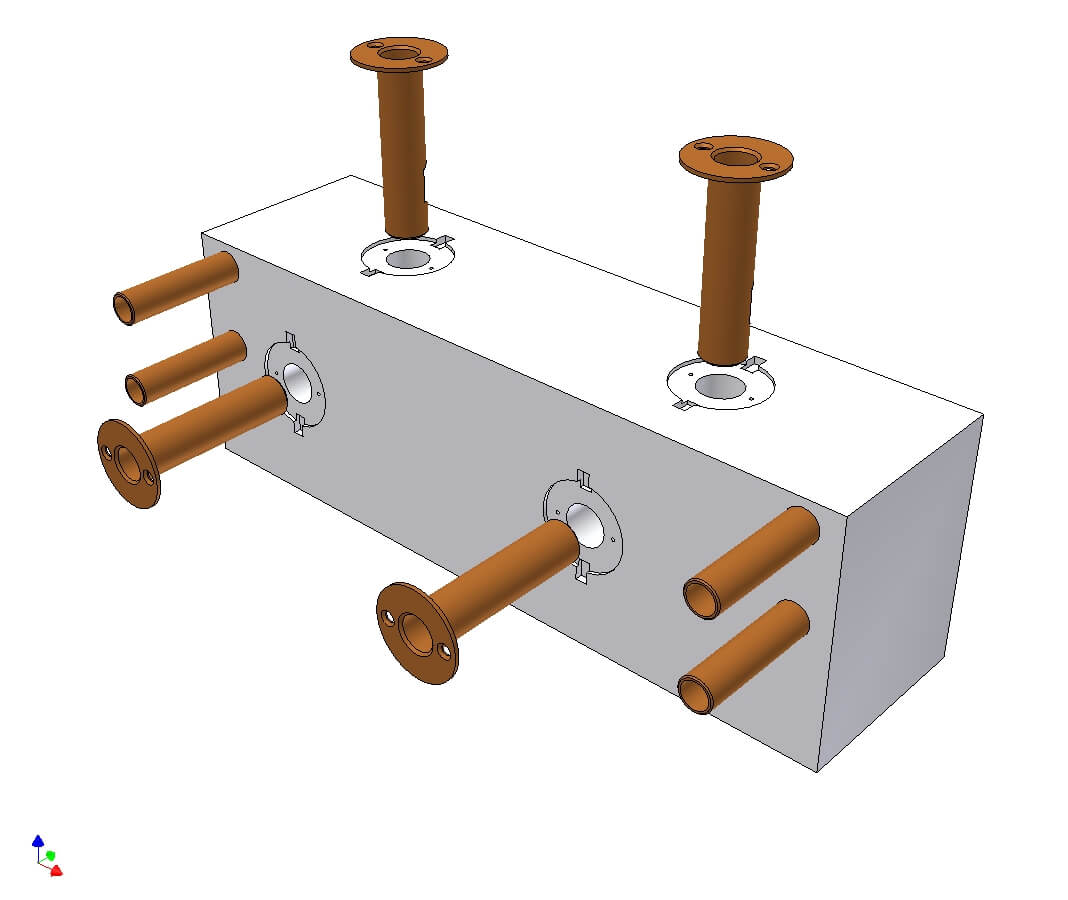

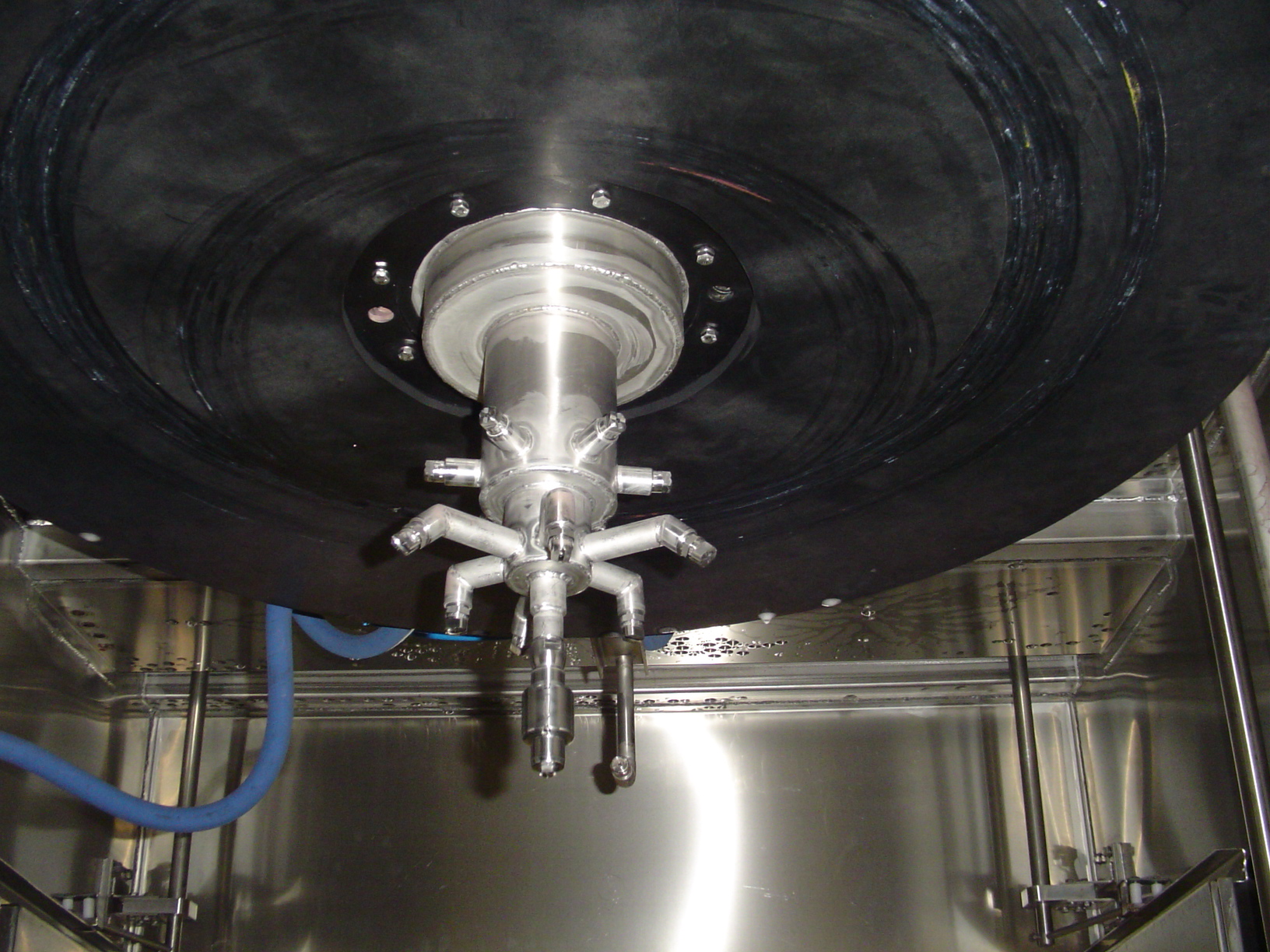

Reading plans, measuring, sawing, cutting, bending, lasering, turning, milling, rolling, punching, drilling, assembling, pointing, welding, deburring, pre-assembly in the workshop, assembly on site…

The big advantage is that, due to the wide range of specialists and machines, we can carry out all this in our own workshop!

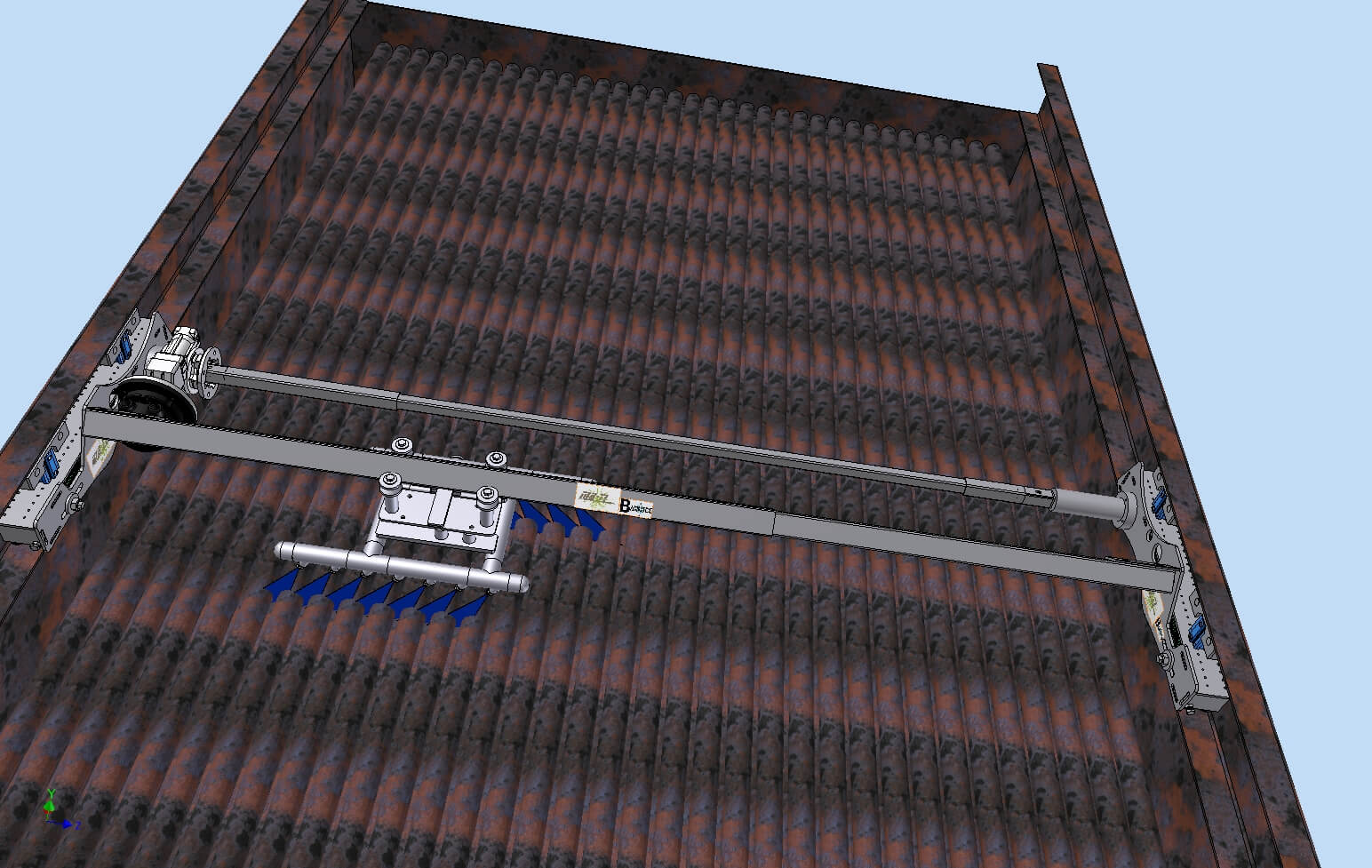

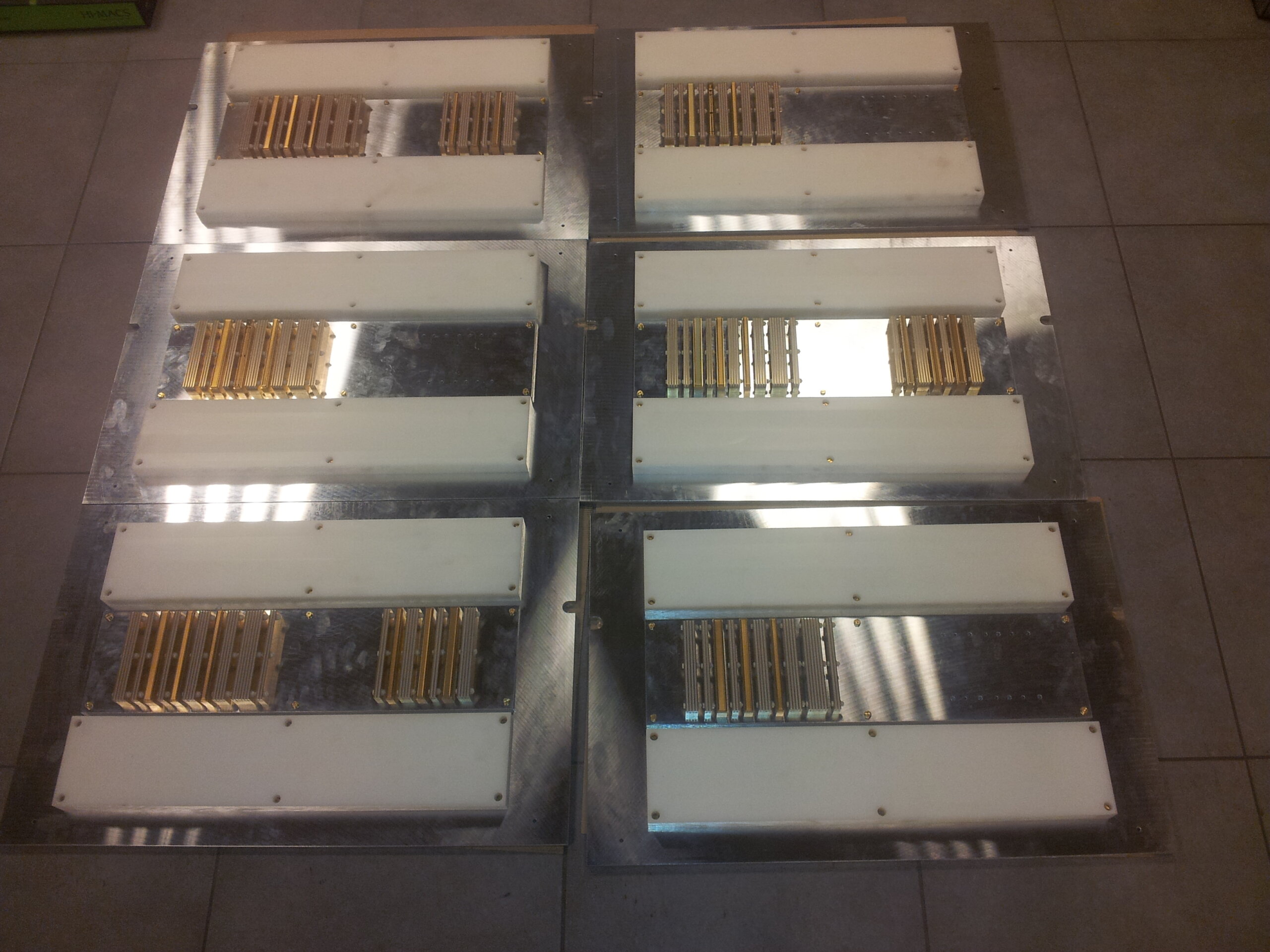

Jeffrey and Abdon operate the laser cutting machine. They know this machine through and through and ensure perfectly lasered pictures.

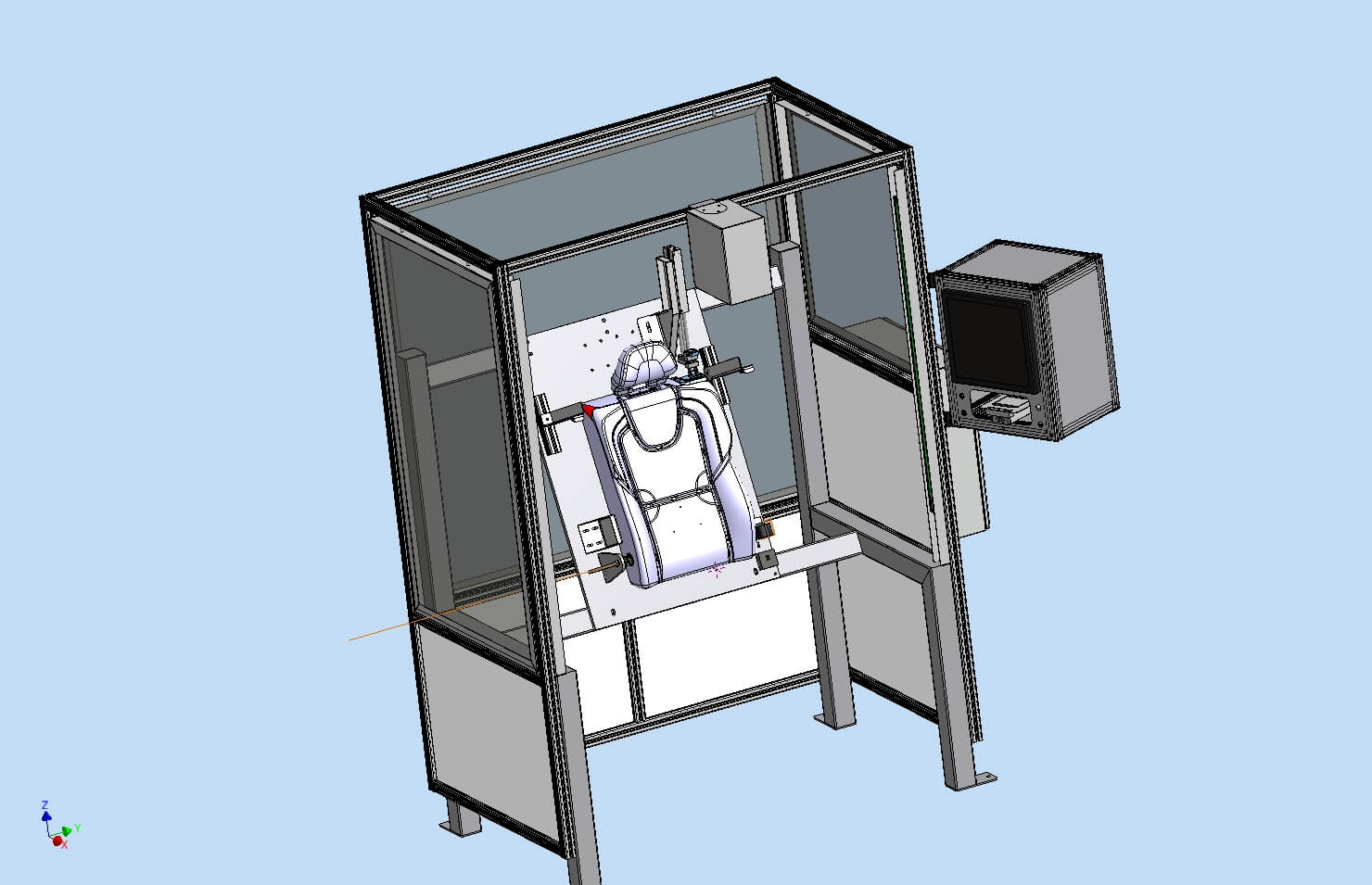

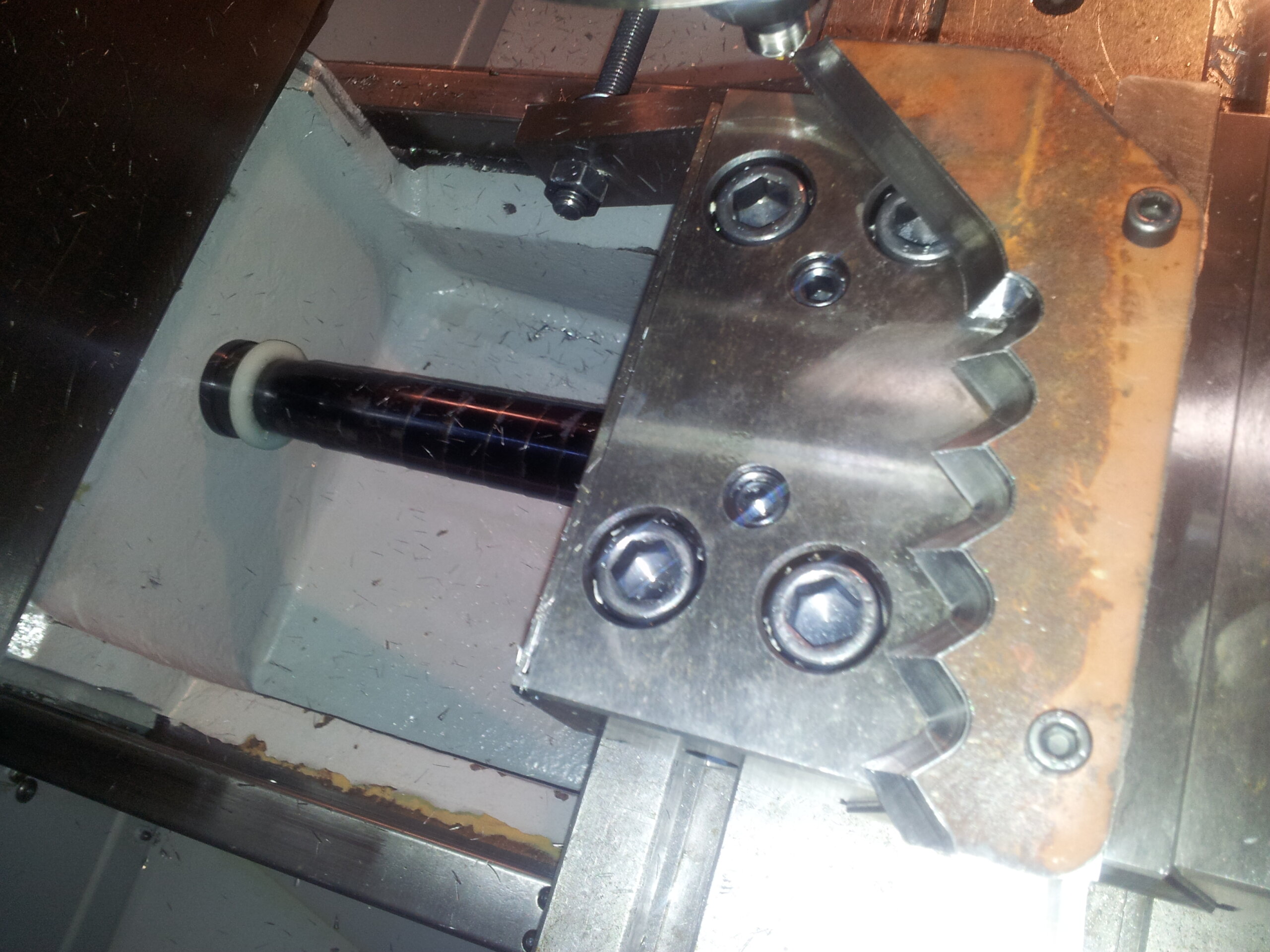

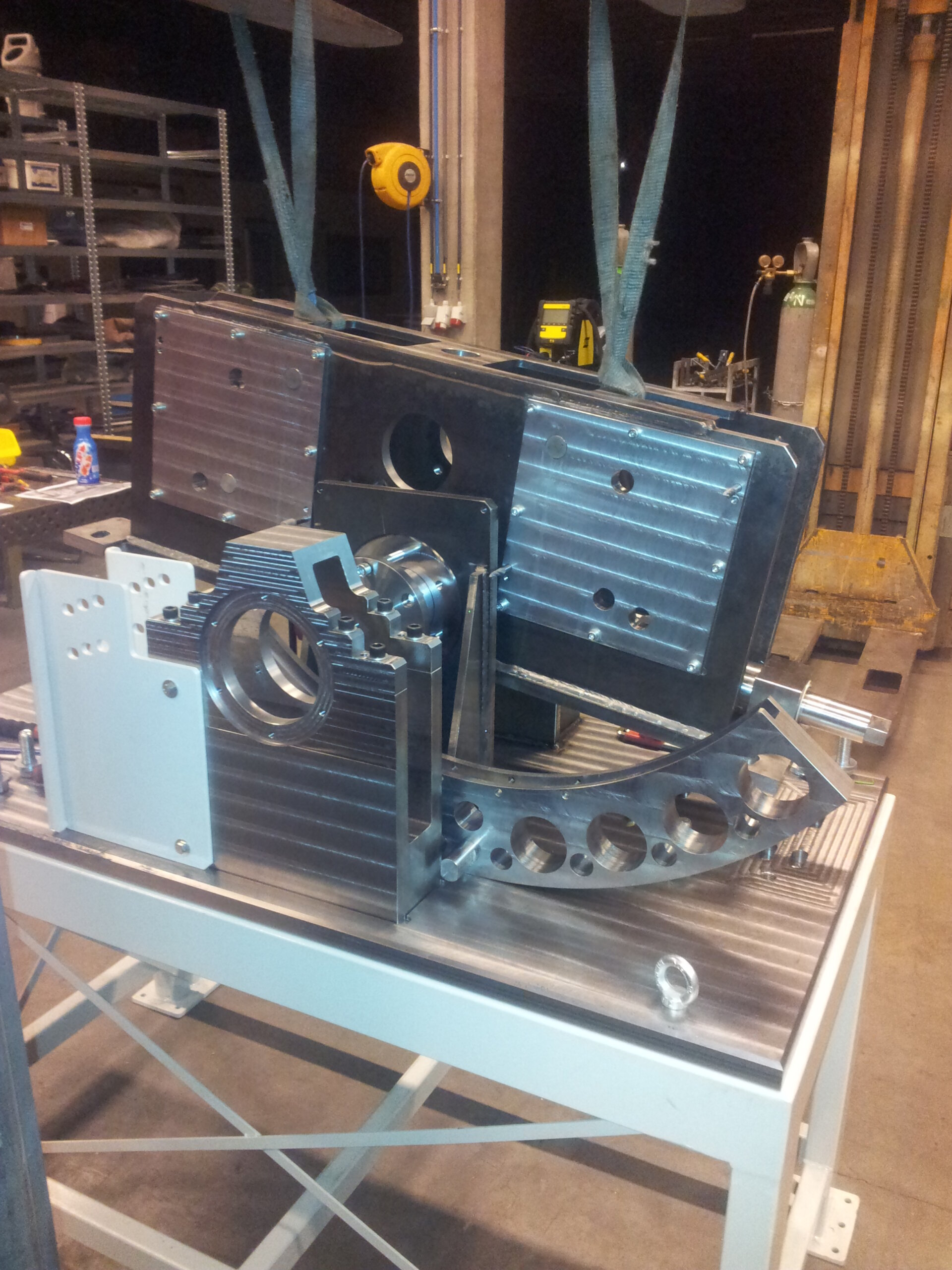

Michiel is a turner/miller at Barotec. He makes the requested pieces for our customers with the greatest care and precision. Michiel works very accurately, which is also reflected in his delivered items.

The other machines are operated by everyone on the team.